Difference between revisions of "BW-RS485"

(Marked this version for translation) |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | <languages/> | ||

| + | <translate> | ||

| + | <!--T:1--> | ||

{{RevisionChanger | hasA = 1 | hasC = 1}} | {{RevisionChanger | hasA = 1 | hasC = 1}} | ||

{{Infobox module | {{Infobox module | ||

| Line 8: | Line 11: | ||

}} | }} | ||

| − | ==RS485 INTERFACE ADAPTER== | + | ==RS485 INTERFACE ADAPTER== <!--T:2--> |

| + | <!--T:3--> | ||

This module is designed for interface adjustment between the | This module is designed for interface adjustment between the | ||

devices which have the RS485 interface and the Smart Home system. | devices which have the RS485 interface and the Smart Home system. | ||

The module has an internal 120Ω terminator resistor. | The module has an internal 120Ω terminator resistor. | ||

| − | ==Features== | + | ==Features== <!--T:4--> |

| + | <!--T:5--> | ||

*Supported protocols: | *Supported protocols: | ||

**ModBus RTU | **ModBus RTU | ||

| Line 22: | Line 27: | ||

*1200 – 115200 baud rate | *1200 – 115200 baud rate | ||

| + | <!--T:6--> | ||

<div class="caution"> | <div class="caution"> | ||

CAUTION! All work related to the installation, connection, setting up, service and support must be carried out by qualified personnel with sufficient skills and experience in working with electrical equipment. | CAUTION! All work related to the installation, connection, setting up, service and support must be carried out by qualified personnel with sufficient skills and experience in working with electrical equipment. | ||

| Line 38: | Line 44: | ||

</div> | </div> | ||

| − | ==Example of connection== | + | ==Example of connection== <!--T:7--> |

| + | <!--T:8--> | ||

[[File:BWRS485C EXA.png|500px]] | [[File:BWRS485C EXA.png|500px]] | ||

| − | ==Module parameters== | + | ==Module parameters== <!--T:9--> |

| + | <!--T:10--> | ||

{{ Mp | {{ Mp | ||

| rs485qty = 1 | | rs485qty = 1 | ||

| Line 57: | Line 65: | ||

}} | }} | ||

| − | ==Module installation and connection procedure== | + | ==Module installation and connection procedure== <!--T:11--> |

| + | <!--T:12--> | ||

#Connect the interface connector. | #Connect the interface connector. | ||

#Connect the CAN connector. | #Connect the CAN connector. | ||

| Line 64: | Line 73: | ||

#Check all equipment for proper operation. | #Check all equipment for proper operation. | ||

| − | ==Module shut-off and deinstallation procedure== | + | ==Module shut-off and deinstallation procedure== <!--T:13--> |

| + | <!--T:14--> | ||

#Disconnect the CAN connector. | #Disconnect the CAN connector. | ||

#Disconnect the interface connector. | #Disconnect the interface connector. | ||

| − | ==HW settings== | + | ==HW settings== <!--T:15--> |

{|class="wikitable" | {|class="wikitable" | ||

|- | |- | ||

| Line 105: | Line 115: | ||

</syntaxhighlight> | </syntaxhighlight> | ||

|} | |} | ||

| + | </translate> | ||

Latest revision as of 14:08, 9 January 2022

| BW-RS485.C | |||||||

|---|---|---|---|---|---|---|---|

| |||||||

| |||||||

| |||||||

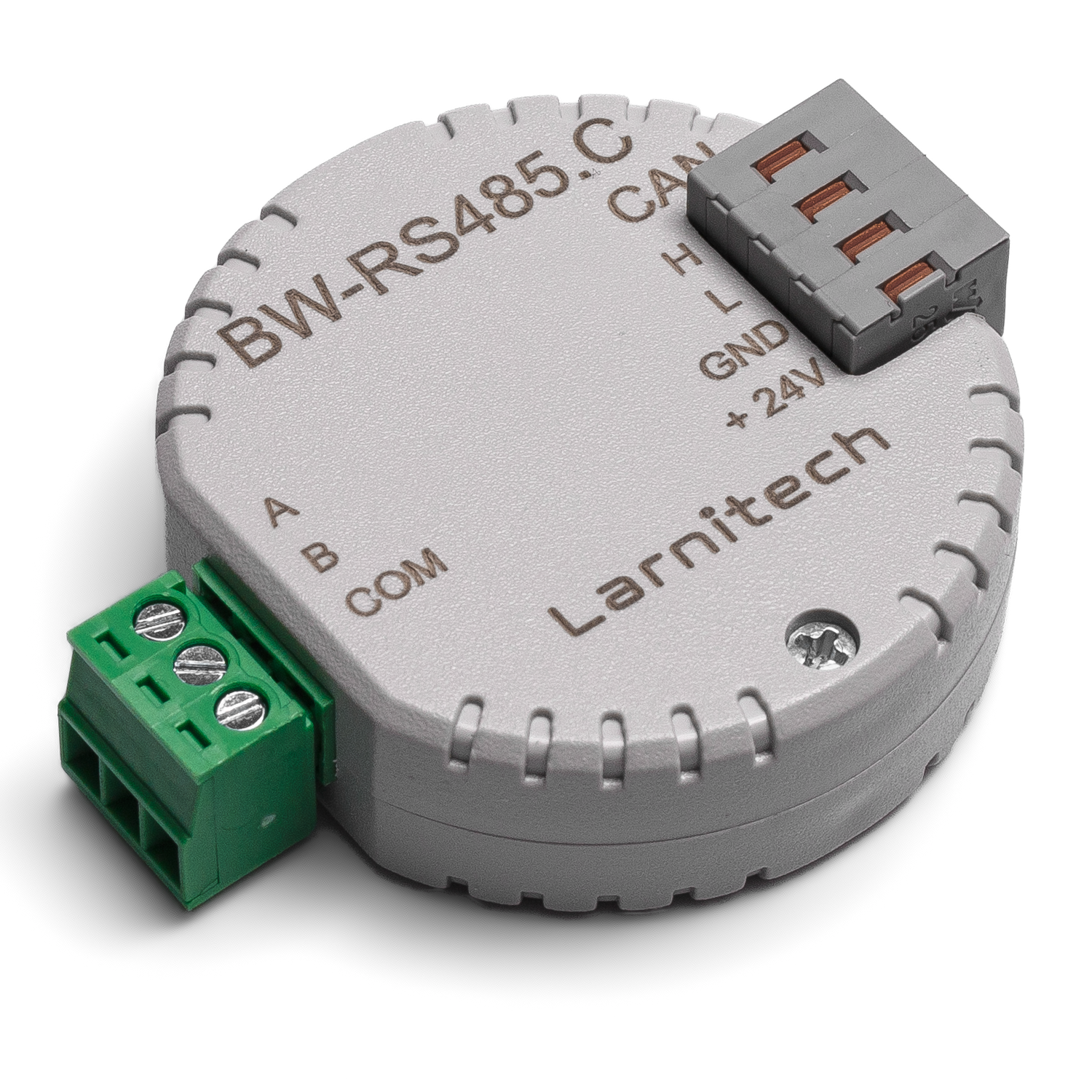

RS485 INTERFACE ADAPTER

This module is designed for interface adjustment between the devices which have the RS485 interface and the Smart Home system. The module has an internal 120Ω terminator resistor.

Features

- Supported protocols:

- ModBus RTU

- DMX512

- Custom protocols

- 1200 – 115200 baud rate

CAUTION! All work related to the installation, connection, setting up, service and support must be carried out by qualified personnel with sufficient skills and experience in working with electrical equipment. To avoid the risk of fire, electric shock, damage to the system and/or personal injury, the system installation and assembly must be performed in accordance with the instructions listed below:

- all connectivity work must be carried out with the power turned OFF;

- use appropriate tools and personal protection against electric shock;

- do not use damaged cables, wires and connectors;

- avoid folding the cables and wires;

- do not apply excessive force to the wires by kinking or pressing them too hard: the inner conductors of the cables and wires may get stripped or damaged;

- do not use the power socket with poor contacts to connect;

- do not exceed the load limit parameters specified in the manual;

- the supply conductors wire section is subject to the specifications for current density limit, insulation type and wire material. Light section can result in cable overheating and fire.

When the power is on, NEVER:

- connect/disconnect the connectors;

- open modules and sensors.

Example of connection

Module parameters

| Parameter name | Value |

|---|---|

| RS485 ports qty | 1 |

| Power supply | 11.5 … 27.5 V DC from CAN |

| Max current(24V) | 25 mA |

| Bus type | CAN (4-wire) |

| Equipment installation type | Free |

| Case material | ABS |

| Protection | IP40 |

| Temperature range | -10 … +50 °C |

| Size | 45x42x14 mm |

| Weight | 15 g |

Module installation and connection procedure

- Connect the interface connector.

- Connect the CAN connector.

- Configure the module using LT setup.

- Check all equipment for proper operation.

Module shut-off and deinstallation procedure

- Disconnect the CAN connector.

- Disconnect the interface connector.

HW settings

| Name | Type, range | SUBID | Default | Description |

|---|---|---|---|---|

| cfg | string | 98 | 9600/8N1 | cfg='SPEED/BPS', where

Example: 1hw="cfg='9600/8N1'"

|

| [Protocol] | string | 98 | — | Protocol setting is described by protocol parameter. The following

protocols are supported:

Example: 1hw="cfg='9600/8N1' modbus"

|

| echo | on; off | 98 | 'off' | For settings check out and testing echo parameter can be used. Module

echo-reply can be turned on or off with the help of this parameter. Echo parameter value:

Example: 1hw="cfg='9600/8N1' echo='off'"

|