Difference between revisions of "DW-HT07"

(Created page with "{{Infobox module | name = DW-HT07.C | image = DW-HT07C.png | outCount = 7 | dimmOut = | peakl = 16A | peakdl = | dt = | inDisc = 12 | i...") |

|||

| Line 14: | Line 14: | ||

{{RevisionChanger | hasA = 1 | hasB = 1 | hasC = 1}} | {{RevisionChanger | hasA = 1 | hasB = 1 | hasC = 1}} | ||

| + | |||

| + | ==7-CHANNEL EXTENSION MODULE== | ||

| + | Has 7 outputs for connecting loads and 12 inputs for connecting | ||

| + | various sensors/buttons. | ||

| + | |||

| + | ==Features== | ||

| + | |||

| + | *7 universal outputs support: | ||

| + | **Lights | ||

| + | **NC/NO heating valves | ||

| + | **Blinds | ||

| + | **1 or 2-pole gates | ||

| + | **1 or 2-pole valves | ||

| + | **NC/NO locks | ||

| + | **Fan coil units | ||

| + | *12 Discreet inputs that support: | ||

| + | **Buttons | ||

| + | **Switches | ||

| + | **Reed switches | ||

| + | **Leak sensors | ||

| + | **Motion detectors | ||

| + | *4 digital inputs for up to 8 temperature sensors | ||

| + | |||

| + | <div class="caution"> | ||

| + | CAUTION! All work related to the installation, connection, setting up, service and support must be carried out by qualified personnel with sufficient skills and experience in working with electrical equipment. | ||

| + | To avoid the risk of fire, electric shock, damage to the system and/or personal injury, the system installation and assembly must be performed in accordance with the instructions listed below: | ||

| + | *all connectivity work must be carried out with the power turned OFF; | ||

| + | *use appropriate tools and personal protection against electric shock; | ||

| + | *do not use damaged cables, wires and connectors; | ||

| + | *avoid folding the cables and wires; | ||

| + | *do not apply excessive force to the wires by kinking or pressing them too hard: the inner conductors of the cables and wires may get stripped or damaged; | ||

| + | *do not use the power socket with poor contacts to connect; | ||

| + | *do not exceed the load limit parameters specified in the manual; | ||

| + | *the supply conductors wire section is subject to the specifications for current density limit, insulation type and wire material. Light section can result in cable overheating and fire. | ||

| + | When the power is on, NEVER: | ||

| + | *connect/disconnect the connectors; | ||

| + | *open modules and sensors. | ||

| + | </div> | ||

| + | |||

| + | ==Overview== | ||

| + | [[File:HT07C VIEW.png|500px]] | ||

| + | |||

| + | ==Example of connection== | ||

| + | [[File:HT07C EXA.png|500px]] | ||

| + | |||

| + | ==Module dimensions== | ||

| + | [[File:HT07 DIMM.png|500px]] | ||

| + | |||

| + | ==Module parameters== | ||

| + | |||

| + | {{ Mp | ||

| + | | outqty = 7 | ||

| + | | digitmaxlen = 30 m | ||

| + | | discinqty = 12 | ||

| + | | digitinqty = 4 | ||

| + | | involtage = 0-250V | ||

| + | | currtype = AC/DC | ||

| + | | maxperch = 16A | ||

| + | | power = 20.0 … 27.5 V DC from CAN | ||

| + | | maxcur24v = 140 mA | ||

| + | | bustype = CAN | ||

| + | | instalation = DIN rail (EN 60715) | ||

| + | | case = ABS | ||

| + | | protection = IP40 | ||

| + | | temprange = -10 … +50 °C | ||

| + | | size = 4U, 69x115x58 mm | ||

| + | | weight = 255 g | ||

| + | }} | ||

| + | |||

| + | ==Connectivity recommendations== | ||

| + | |||

| + | In order to protect the actuator and loads connected to it, installing a circuit breaker is recommended. | ||

| + | The nominal value of the circuit breaker should be calculated based on the maximum total load of connected | ||

| + | devices and at the same time should not significantly exceed the maximum permissible characteristics of the actuator. | ||

| + | Depending on the requirements, you can use one circuit breaker for one actuator (it is recommended) | ||

| + | or one circuit breaker per each group of connected loads, or, if necessary, a separate circuit breaker can be installed | ||

| + | for each load. | ||

| + | |||

| + | ==Connection of actuators== | ||

| + | |||

| + | <div class="caution"> Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire. | ||

| + | If free (unused) channels remain in a given group after a curtain/jalousie/shutter actuator with low-voltage control or gate actuator has been connected to it, these channels need to be left unused. (Do not connect other devices to them!) </div> | ||

| + | |||

| + | ===Connection of the lights/electric contactor/heating thermal actuator=== | ||

| + | |||

| + | [[File:lamps.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='LLL----'" | ||

| + | </syntaxhighlight> | ||

| + | |||

| + | |||

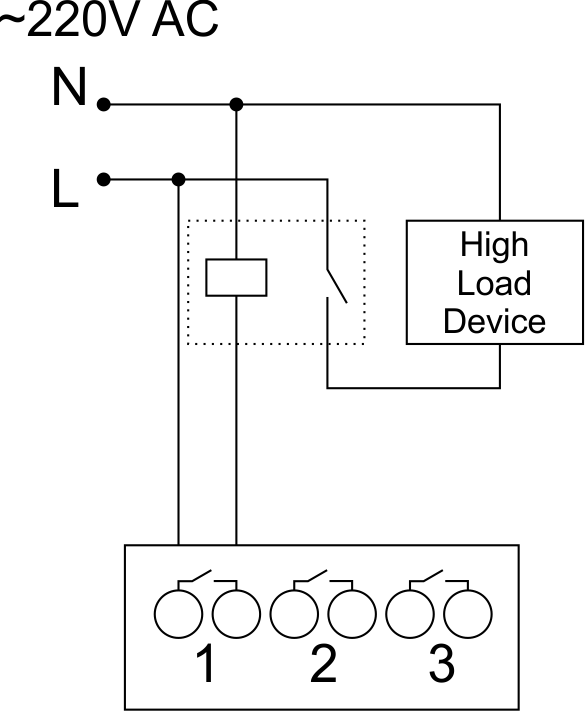

| + | ===Connection of high load device=== | ||

| + | |||

| + | {| class="wikitable" style="width:800px"; | ||

| + | |- | ||

| + | |[[File:Contactor.png|200px|Contactor]]|| style="margin:20px"|Recomended contactors: | ||

| + | *ABB ESB series | ||

| + | *Schneider Acti 9 iCT series | ||

| + | *Hager ESC series. | ||

| + | |} | ||

| + | |||

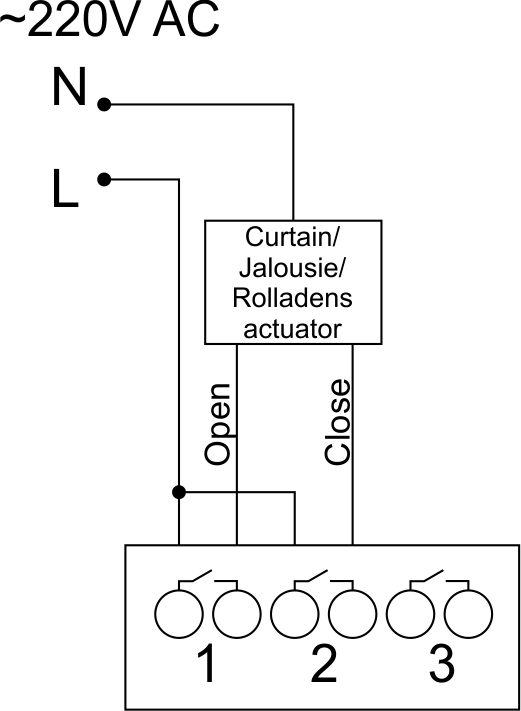

| + | ===Connection of curtain/jalousie/shutter actuator with 220V force control=== | ||

| + | |||

| + | [[File:Pjalousie.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='B------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

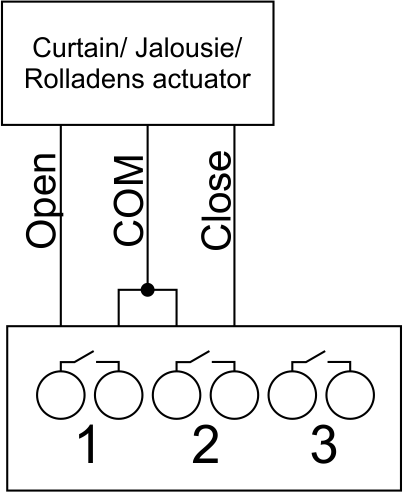

| + | ===Connection of curtain/jalousie/shutter actuator with low-voltage control=== | ||

| + | |||

| + | [[File:Ljalousie.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='B------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

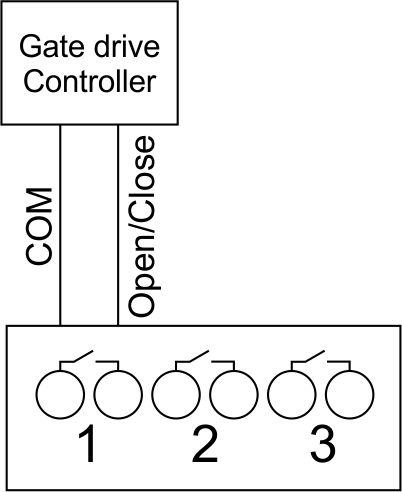

| + | ===Connection of single-pole gate actuator=== | ||

| + | |||

| + | [[File:1pgate.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='X------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

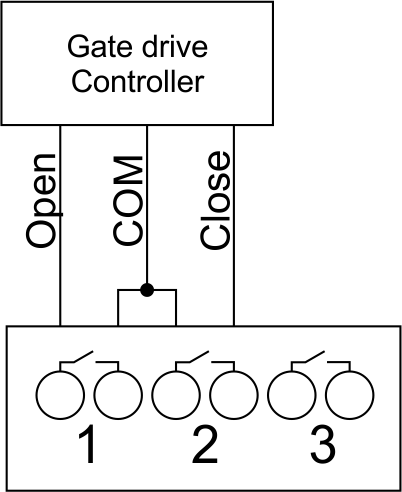

| + | ===Connection of double-pole gate actuator=== | ||

| + | |||

| + | [[File:2pgate.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='G------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

| + | |||

| + | |||

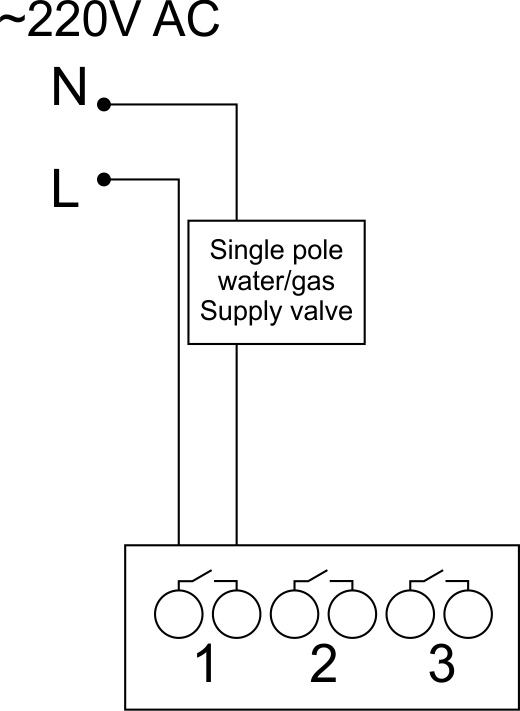

| + | ===Connection of single-pole water/gas supply valve=== | ||

| + | |||

| + | [[File:1pvalve.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='R------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

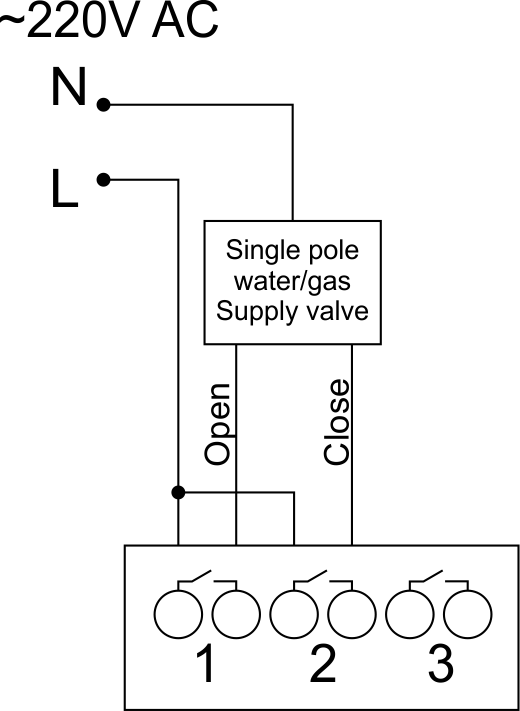

| + | ===Connection of double-pole water/gas supply valve=== | ||

| + | |||

| + | [[File:2pvalve.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='V------'" | ||

| + | </syntaxhighlight> | ||

| + | |||

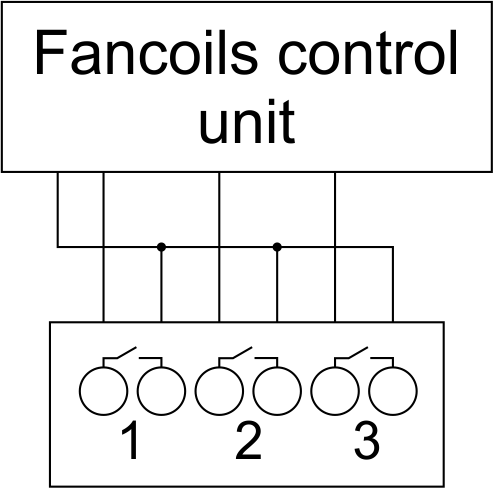

| + | ===Connection of fancoil control unit=== | ||

| + | |||

| + | [[File:fancoil.png|200px]]<br> | ||

| + | Sample HW for this configuration | ||

| + | <syntaxhighlight lang="xml" line> | ||

| + | hw="out='FFF----'" | ||

| + | </syntaxhighlight> | ||

| + | |||

| + | ===Example of sensors connection=== | ||

| + | |||

| + | [[File:SensorsConn4.png|200px]]<br> | ||

| + | 2-wire connection recommended | ||

| + | |||

| + | ==Indication of module operation== | ||

| + | |||

| + | ===Bootloader=== | ||

| + | {{indication}} | ||

| + | |||

| + | ===Firmware mode=== | ||

| + | {{indicationfw | ||

| + | |err1 = 1 | ||

| + | |err2 = 1}} | ||

Revision as of 09:49, 22 July 2021

| DW-HT07.C | |||||||

|---|---|---|---|---|---|---|---|

| |||||||

| |||||||

| |||||||

| |||||||

7-CHANNEL EXTENSION MODULE

Has 7 outputs for connecting loads and 12 inputs for connecting various sensors/buttons.

Features

- 7 universal outputs support:

- Lights

- NC/NO heating valves

- Blinds

- 1 or 2-pole gates

- 1 or 2-pole valves

- NC/NO locks

- Fan coil units

- 12 Discreet inputs that support:

- Buttons

- Switches

- Reed switches

- Leak sensors

- Motion detectors

- 4 digital inputs for up to 8 temperature sensors

CAUTION! All work related to the installation, connection, setting up, service and support must be carried out by qualified personnel with sufficient skills and experience in working with electrical equipment. To avoid the risk of fire, electric shock, damage to the system and/or personal injury, the system installation and assembly must be performed in accordance with the instructions listed below:

- all connectivity work must be carried out with the power turned OFF;

- use appropriate tools and personal protection against electric shock;

- do not use damaged cables, wires and connectors;

- avoid folding the cables and wires;

- do not apply excessive force to the wires by kinking or pressing them too hard: the inner conductors of the cables and wires may get stripped or damaged;

- do not use the power socket with poor contacts to connect;

- do not exceed the load limit parameters specified in the manual;

- the supply conductors wire section is subject to the specifications for current density limit, insulation type and wire material. Light section can result in cable overheating and fire.

When the power is on, NEVER:

- connect/disconnect the connectors;

- open modules and sensors.

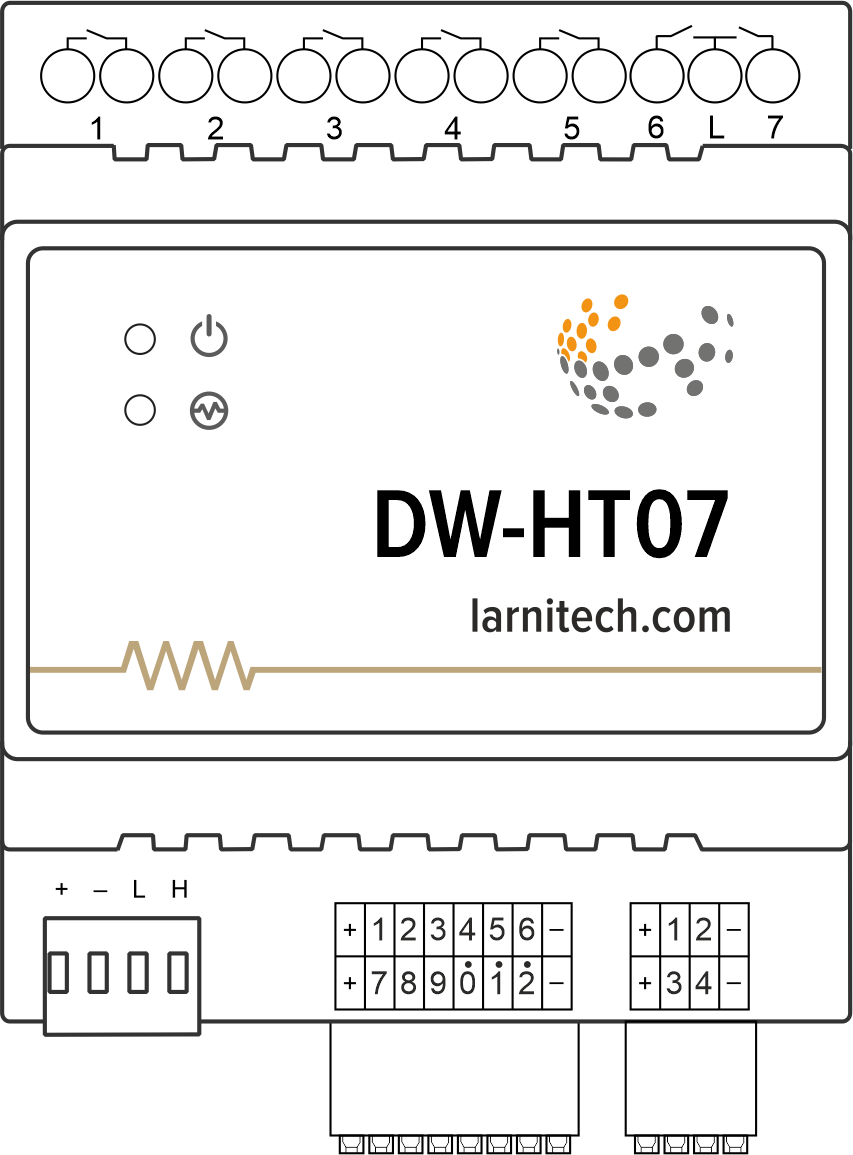

Overview

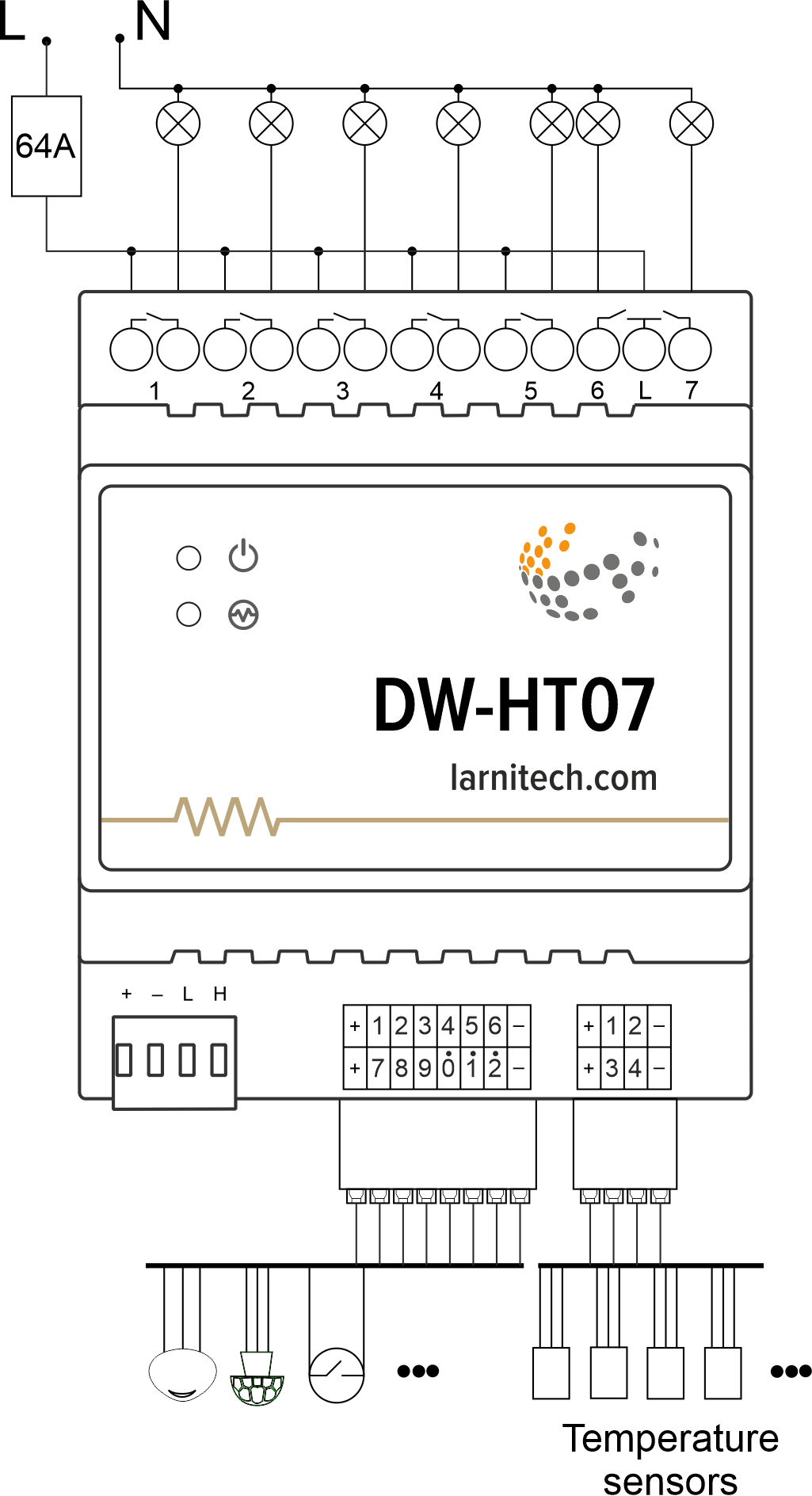

Example of connection

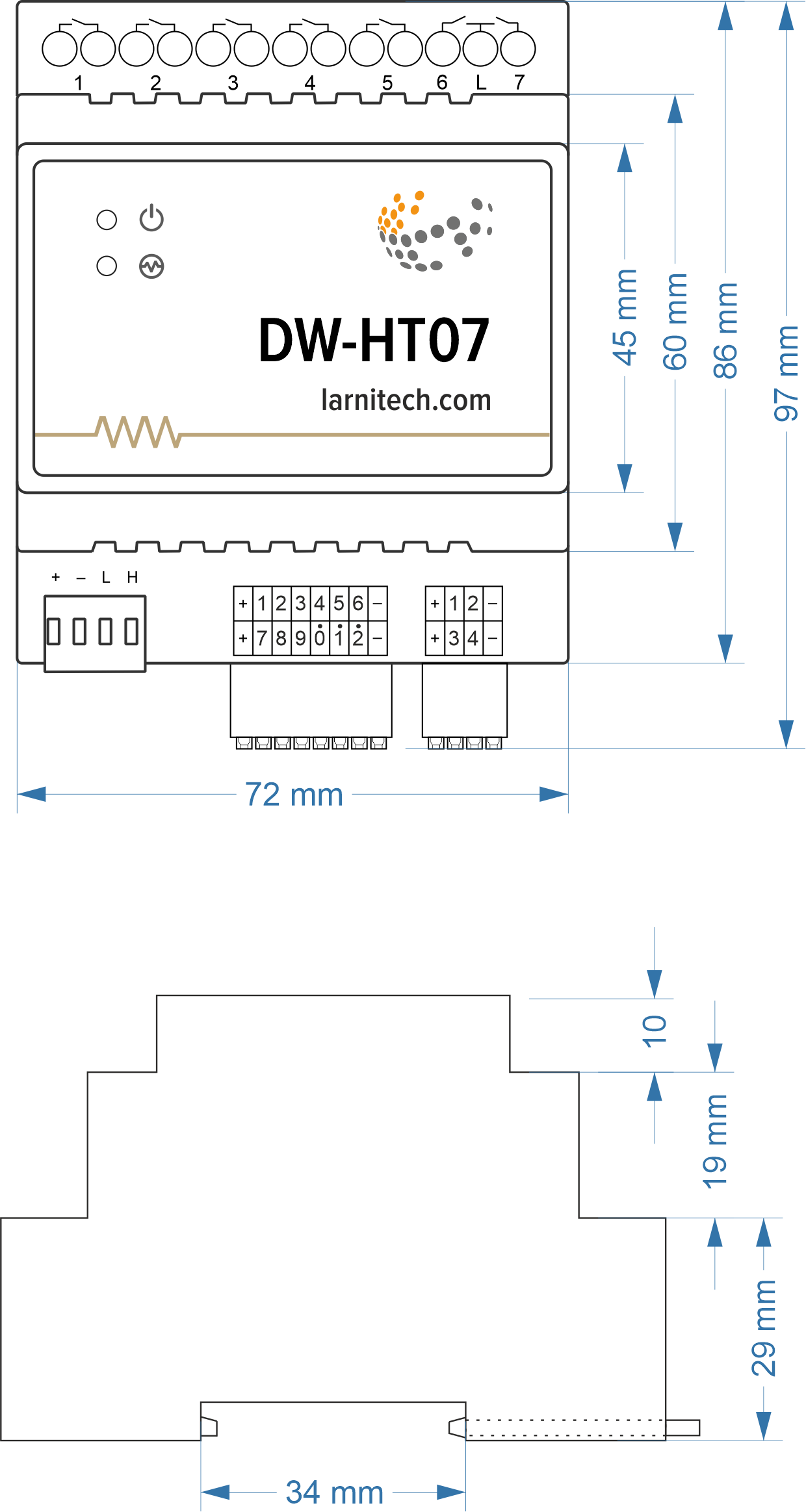

Module dimensions

Module parameters

| Parameter name | Value |

|---|---|

| Output channels qty | 7 |

| Digital line maximum length | 30 m |

| Discrete input channels qty | 12 |

| Digital input channels qty | 4 |

| Input voltage | 0-250V |

| Current type | AC/DC |

| Max load per channel | 16A |

| Power supply | 20.0 … 27.5 V DC from CAN |

| Max current(24V) | 140 mA |

| Bus type | CAN |

| Equipment installation type | DIN rail (EN 60715) |

| Case material | ABS |

| Protection | IP40 |

| Temperature range | -10 … +50 °C |

| Size | 4U, 69x115x58 mm |

| Weight | 255 g |

Connectivity recommendations

In order to protect the actuator and loads connected to it, installing a circuit breaker is recommended. The nominal value of the circuit breaker should be calculated based on the maximum total load of connected devices and at the same time should not significantly exceed the maximum permissible characteristics of the actuator. Depending on the requirements, you can use one circuit breaker for one actuator (it is recommended) or one circuit breaker per each group of connected loads, or, if necessary, a separate circuit breaker can be installed for each load.

Connection of actuators

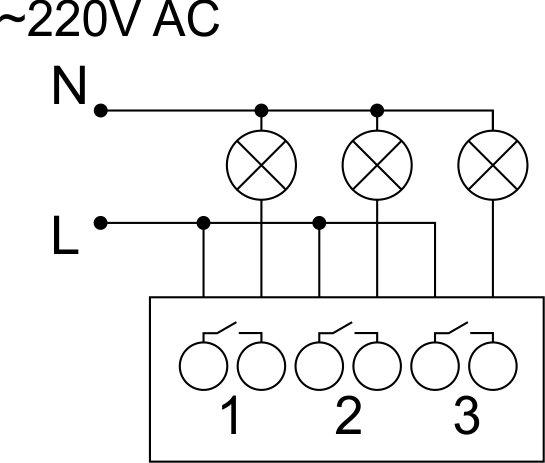

Connection of the lights/electric contactor/heating thermal actuator

Sample HW for this configuration

1hw="out='LLL----'"

Connection of high load device

|

Recomended contactors:

|

Connection of curtain/jalousie/shutter actuator with 220V force control

Sample HW for this configuration

1hw="out='B------'"

Connection of curtain/jalousie/shutter actuator with low-voltage control

Sample HW for this configuration

1hw="out='B------'"

Connection of single-pole gate actuator

Sample HW for this configuration

1hw="out='X------'"

Connection of double-pole gate actuator

Sample HW for this configuration

1hw="out='G------'"

Connection of single-pole water/gas supply valve

Sample HW for this configuration

1hw="out='R------'"

Connection of double-pole water/gas supply valve

Sample HW for this configuration

1hw="out='V------'"

Connection of fancoil control unit

Sample HW for this configuration

1hw="out='FFF----'"

Example of sensors connection

200px

2-wire connection recommended

Indication of module operation

Bootloader

| Indicator | Status | Description |

|---|---|---|

| Device in bootloader | ||

| Downloading firmware | ||

| Flashing firmware |

Firmware mode

| Indicator | Status | Description |

|---|---|---|

| Identification | ||

| Operational mode | ||

Error | ||

| Lost connection to server | ||

| Overheat |