Difference between revisions of "Metaforsa 3/3.plus/sr"

(Created page with "{| class="wikitable" style="width:800px"; |- |colspan="2" style="background-color:#dededf" |'''Oprez: Pre nego što primenite napajanje na opterećenje, uverite se da je izlaz...") Tags: Mobile web edit Mobile edit |

(Created page with "====Priključak dvopolnog ventila za dovod vode/gasa====") Tags: Mobile web edit Mobile edit |

||

| Line 345: | Line 345: | ||

| − | ==== | + | ====Priključak dvopolnog ventila za dovod vode/gasa==== |

{| class="wikitable" style="width:800px"; | {| class="wikitable" style="width:800px"; | ||

Revision as of 14:08, 8 April 2024

| MF3/MF3.plus | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

Uvod

Instruktsiya z montazhu METAFORSA SMART HOUSE opysuye poryadok yoho montazhu, montazhu, ekspluatatsiyi ta nalashtuvannya. Pry roboti z systemoyu neobkhidno suvoro dotrymuvatysya vsikh vymoh, vykladenykh u tsiy instruktsiyi. Nedotrymannya mozhe pryzvesty do poshkodzhennya prystroyu, yoho polomky, urazhennya elektrychnym strumom, pozhezhi ta inshykh naslidkiv. Vyrobnyk zalyshaye za soboyu pravo vnosyty zminy v tsey posibnyk bez poperednʹoho povidomlennya. Tsey posibnyk ye nevidʺyemnoyu chastynoyu systemy ta maye zalyshatysya u kintsevoho korystuvacha.

Karakteristike

- Podržava 10 univerzalnih izlaza:

- Lights

- NC/NO ventili za grejanje

- Blinds

- 1 ili 2-polne kapije

- 1 ili 2-polni ventili

- NC/NO brave

- Fan coil jedinice

- 4 izlaza za zatamnjivanje

- 28 ulaza koji podržavaju:

- Dugmad

- LED dugmad

- Prekidači

- Reed prekidači

- Senzori curenja

- Detektori pokreta

- Senzori temperature

- LED trake

- 3-4-5 kanalne RGB trake

- VS2812B trake

- RS485 uređaji (samo za Metaforsa 3.plus)

- Priključak za proširenje

- Releji sa AgSnO2 kontaktima predviđeni za udarnu struju od 80A 20ms

- Klaud veza i kontrola svih kućnih sistema

- Upravljanje glasom (Siri, Aleka, Google Home)

Zahtevi za bezbednost

Da biste izbegli rizik od požara, strujnog udara, oštećenja sistema i/ili ličnih povreda, instalacija i montaža sistema se moraju izvršiti u skladu sa uputstvima navedenim u nastavku:

- svi radovi na priključenju moraju se izvoditi bez struje;

- koristite odgovarajući alat i ličnu zaštitu od strujnog udara;

- ne koristite oštećene kablove, žice i konektore;

- izbegavajte savijanje kablova i žica;

- nemojte štipati ili savijati kablove i žice primenom prekomerne sile. U suprotnom, unutrašnji provodnici kabla i žica mogu biti ogoljeni ili slomljeni;

- za povezivanje nemojte koristiti utičnicu sa lošim kontaktima;

- ne prekoračite ograničenje parametara opterećenja navedeno u ovom priručniku;

- presek žice provodnika za napajanje podleže specifikacijama za ograničenje gustine struje, tip izolacije i materijal žice. Lagani deo može dovesti do pregrevanja kabla i požara.

Kada radite sa sistemom nakon napajanja naponom NIKAD:

- izvršiti spajanje/isključivanje konektora;

- otvoreni moduli i senzori.

Konfiguracija sistema i svrha

Svrha sistema

METAFORSA SMART HOUSE je gotovo rešenje za automatizaciju stambenih i poslovnih prostora, hotelskih kompleksa koje uključuje najpoželjnije karakteristike Smart House.

Uređaj ima 10 kontrolnih kanala, 4 kanala za zatamnjivanje i 28 ulaznih kanala br.

| Univerzalni izlazi se mogu koristiti za kontrolu: | Univerzalni ulazi vam omogućavaju da povežete: |

|---|---|

| Rasveta | Dugmad/LED dugmad/preklopne jedinice |

| Utičnice | Magnetni prekidači |

| Podno grejanje | Senzori curenja |

| Zavesa | Detektori pokreta |

| Pogoni za kapije | Senzori temperature |

| Vodovod | LED trake/3-4-5 kanalne RGB trake/VS2812B trake |

| Ventili za grejanje | RS485 uređaji* |

<noviki>*</noviki> – Samo za Metaforsa 3.plus

Port za proširenje

Port za proširenje vam omogućava da nadogradite sistem povezivanjem pomoćne opreme, kao što je kontrolni modul za LED osvetljenje, zatamnjenje, merne uređaje i druge elemente.

Paket, koji je potpuno spreman za instalaciju, uključuje osnovni hardver i softver.

Sadržaj paketa

Paket standardno dolazi sa:

| Mainframe METAFORSA 3/3.plus | 1 kom |

| Napajanje MEANVELL DR-15-12 | 1 kom |

| Senzor pokreta CV-MSD | 3 kom |

| Senzor curenja FV-VL.B | 2 kom |

| Element osetljiv na temperaturu FV-TS | 4 kom |

| Magnetni reed prekidač (senzor položaja prozora/vrata) | 4 kom |

| Filter šuma za Ethernet kabl | 1 kom |

| Kabl za napajanje | 1 kom |

Osnovne tehničke specifikacije sistema

Osnovne specifikacije i karakteristike modula METAFORSA 3/3.plus prikazane su u tabeli 1{| class="wikitable"

|+ text-align="left"|Tabela 1

|-

!Specifikacija !! Značenje

|-

|colspan="2"|Izlazni portovi

|-

| Broj preklopljenih kanala || 10

|-

| Broj preklopljenih grupa|| 10

|-

| Broj kanala za zatamnjivanje || 4

|-

| Napon komutacije || 0-250 V AC/DC

|-

| Vršno opterećenje (jedan kanal) || 16A

|-

| Vršno opterećenje (uređaj) || 160A

|-

| Maksimalno opterećenje po kanalu za zatamnjenje || 0,5 A (110 V na 220 V)

|-

| Tip dimera || MOSFET

|-

| Tip opterećenja dimera || R,C

|-

| Tip zatamnjivanja || zadnja ivica

|-

| Vrsta priključka kabla za napajanje || konektor

|-

|Dozvoljeni deo kabla za napajanje za povezivanje u utičnicu:

jednožilni kabl

kabl sa više provodnika

kabl sa više provodnika||

0,5 … 4mm2

0,5 … 4mm2

0,5 … 2,5 mm2

|-

|colspan="2"|Ulazni portovi

|-

|Broj diskretnih ulaza || 28

|-

|Maksimalna struja na konektorima jednosmernog napona || 5 mA*

|-

|colspan="2"|Ostalo

|-

|Radna temperatura okoline || 0 … +45°S

|-

|temperatura skladištenja/transporta || -10 … +50°S

|-

|Dozvoljena vlažnost || 0 … 95% (bez kondenzacije)

|-

|Napajanje || 11,5 … 27,5 V DC

24V, 0,75A Preporučeno

|-

|Maksimalna potražnja || 0.5A

|-

|Dostupni interfejsi || Ethernet, CAN

|-

|Tip autobusa || CAN (4-žični)

|-

|CAN (4-vire) || 800 m** (upredeni par CAT5e)

|-

|CAN tip žice || FTP Cat 5E

|-

|CAN tip veze || Connector

|-

|Maksimalna dužina digitalne linije || 30 m

|-

|Tip digitalne linije || UTP/FTP Cat 5E

|-

|LAN maksimalna dužina || 100 m

|-

|vrsta LAN žice || UTP/FTP Cat 5E

|-

|vrsta LAN veze || Konektor RJ-45

|-

|RS485 portovi kol || 1***

|-

|Brzina prenosa podataka || 1200-115200 b/s***

|-

|Dimenzionalne specifikacije || 9U, 156k90k58 mm

|-

|Materijal školjke || ABS

|-

|Cusing || IP40

|-

|Tip ugradnje opreme || DIN šina (EN 60715)

|-

|Težina || 400 g

|}

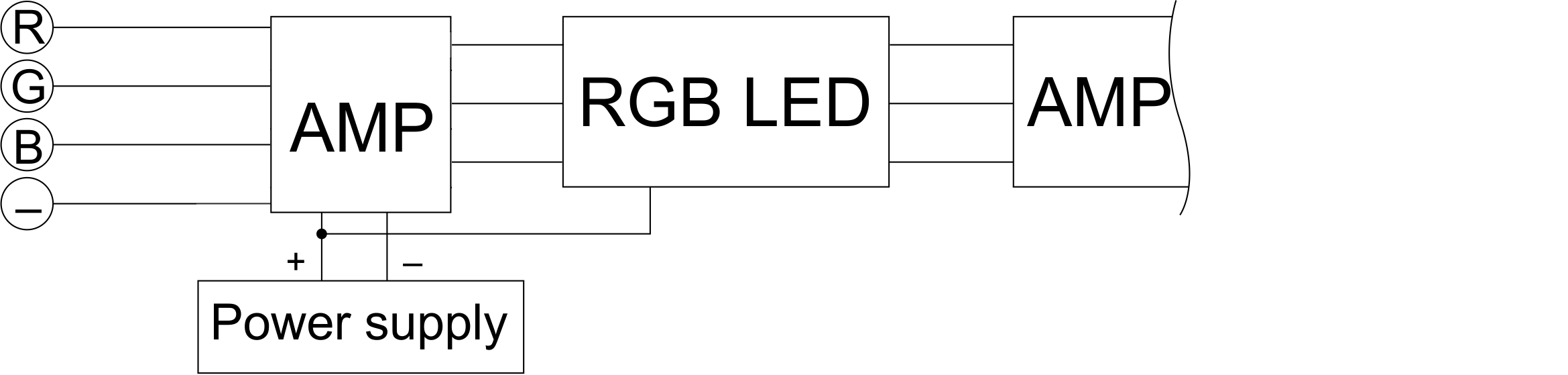

<noviki>*</noviki> – Izlazne kanale treba povezati samo pomoću pojačala koje koristi 5V PVM signal sa IO izlaza kao ulaz

** – potrebno je instaliranje dodatnih jedinica za napajanje za duge linije; maksimalna dužina linije može biti smanjena različitim faktorima interferencije

*** – Samo za Metaforsa 3.plus

Opšta struktura sistema

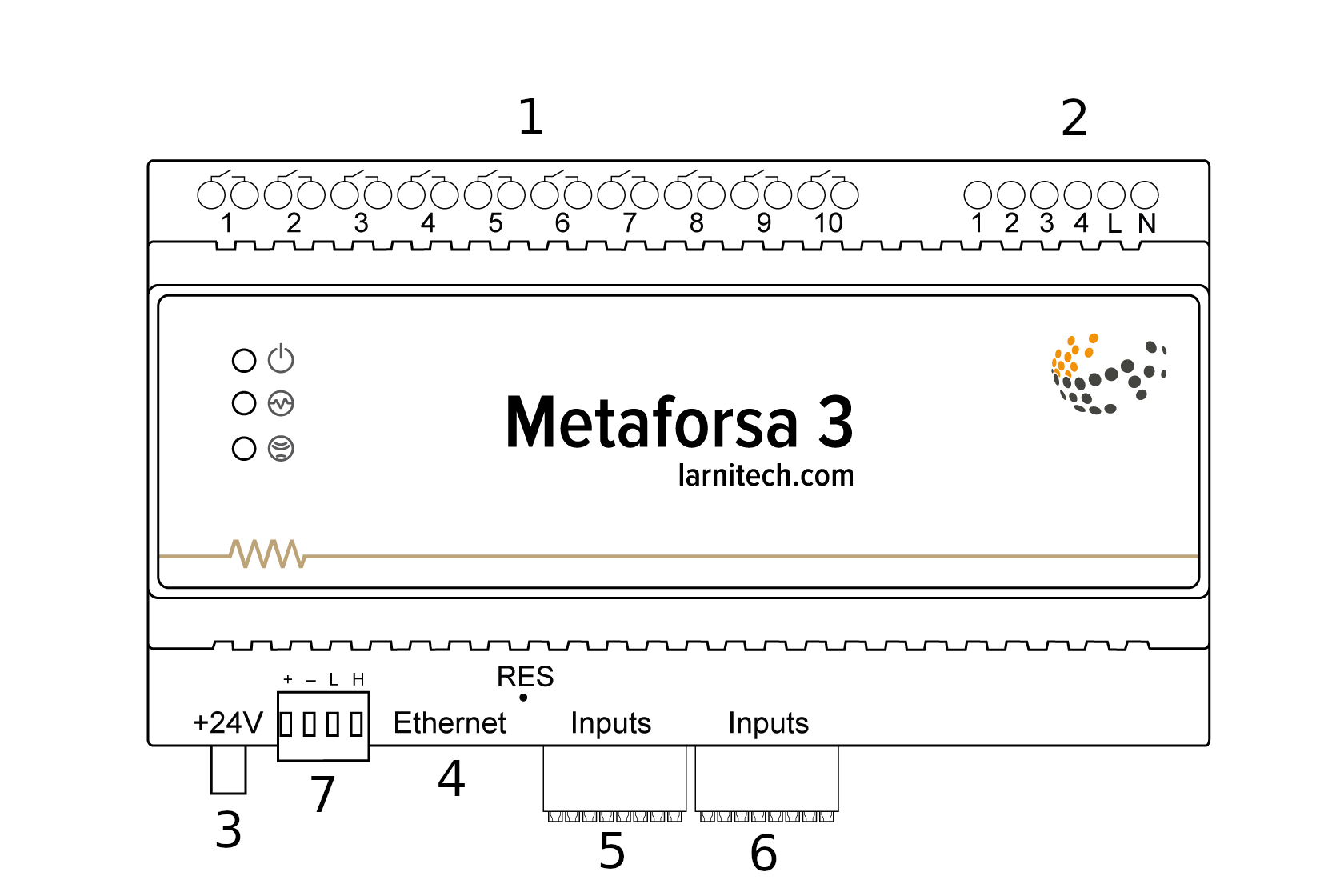

Opšti prikaz modula je prikazan na 'sl. 1

| 1 | — konektor za primenu opterećenja |

| 2 | — konektor za primenu lampi za prigušivanje |

| 3 | - konektor za napajanje |

| 4 | — Ethernet mrežni konektor |

| 5-6 | — konektori za univerzalne ulazno/izlazne kanale |

| 7 | — konektor za modul za proširenje. |

Pregled eksternih konektora uređaja METAFORSA:

Na vrhu kućišta (sl. 1) nalazi se:

- konektor (1) — Veza uređaja;

- konektor (2) — priključak sijalica za prigušivanje;

Na dnu kućišta (sl. 1) nalazi se:

- konektor (3) — priključak za napajanje modula;

- konektor (4) — Ethernet mrežna veza;

- konektori (5-6) — povezivanje univerzalnih ulazno-izlaznih kanala – dugmad, reed prekidači, LED dugmad, senzori curenja, senzori pokreta, temperaturni senzori, LED trake, 3-4-5 kanalne RGB trake, VS2812B trake, RS485 uređaji ( Samo za Metaforsa 3.plus);

- konektor (7) — priključak modula za proširenje.

Fizička konfiguracija i dodela kontaktnih tačaka svakog konektora su prikazani u tabela 2.

| Konektor | Kontakt | Zadatak |

|---|---|---|

|

1-10 | Primena opterećenja (svetleće lampe, termički aktuatori, itd.) |

| D1-4, L, N | Aplikacija opterećenja (zatamnjenje lampe) | |

| Indikatori statusa uređaja | Indikatori statusa modula su opisani u tabela 3 | |

|

+24V GND |

+24V — napajanje modula preko eksternog napajanja od 24 V GND — zajedničko |

|

RJ45 | Konektor za LAN povezivanje |

| In1-14, In15-28 GND | Povezivanje kontrolnih uređaja (dugmad, LED dugmad, magnetni reed prekidači, detektori pokreta, senzori curenja, senzori temperature, itd.): In1 … In28 — logički ulazi GND — zajednički | |

|

VCC GND L H |

Povezivanje eksternih modula za CAN-bus VSS — 24V izlaz za napajanje eksternih uređaja GND — uobičajeno L — CAN-L sabirnica podataka H — CAN-H magistrala podataka |

| Indicator | Status | Description |

|---|---|---|

| Power | Power | |

| Power not available | ||

| Activity | Data communication | |

| Data communication not available | ||

| Error | No errors | |

| Communication error | ||

| Module overheat | ||

| Dimmer outputs module overload | ||

| Absence of power on dimmers, if in configuration |

Instalacija i montaža sistema

Pre povezivanja sistema, morate:

- postavite senzor i aktuatore (ako nisu unapred instalirani), podesite senzore i aktuatore;

- lokacija modula i napajanja.

Napomena: Modul mora biti instaliran blizu izvora napona napajanja.

- Snaga sklopa prekidača mora biti u skladu sa kapacitetom opterećenja;

- Ništa drugo osim faznih provodnika se ne može povezati na modul, neutralna žica je odvojeno povezana.

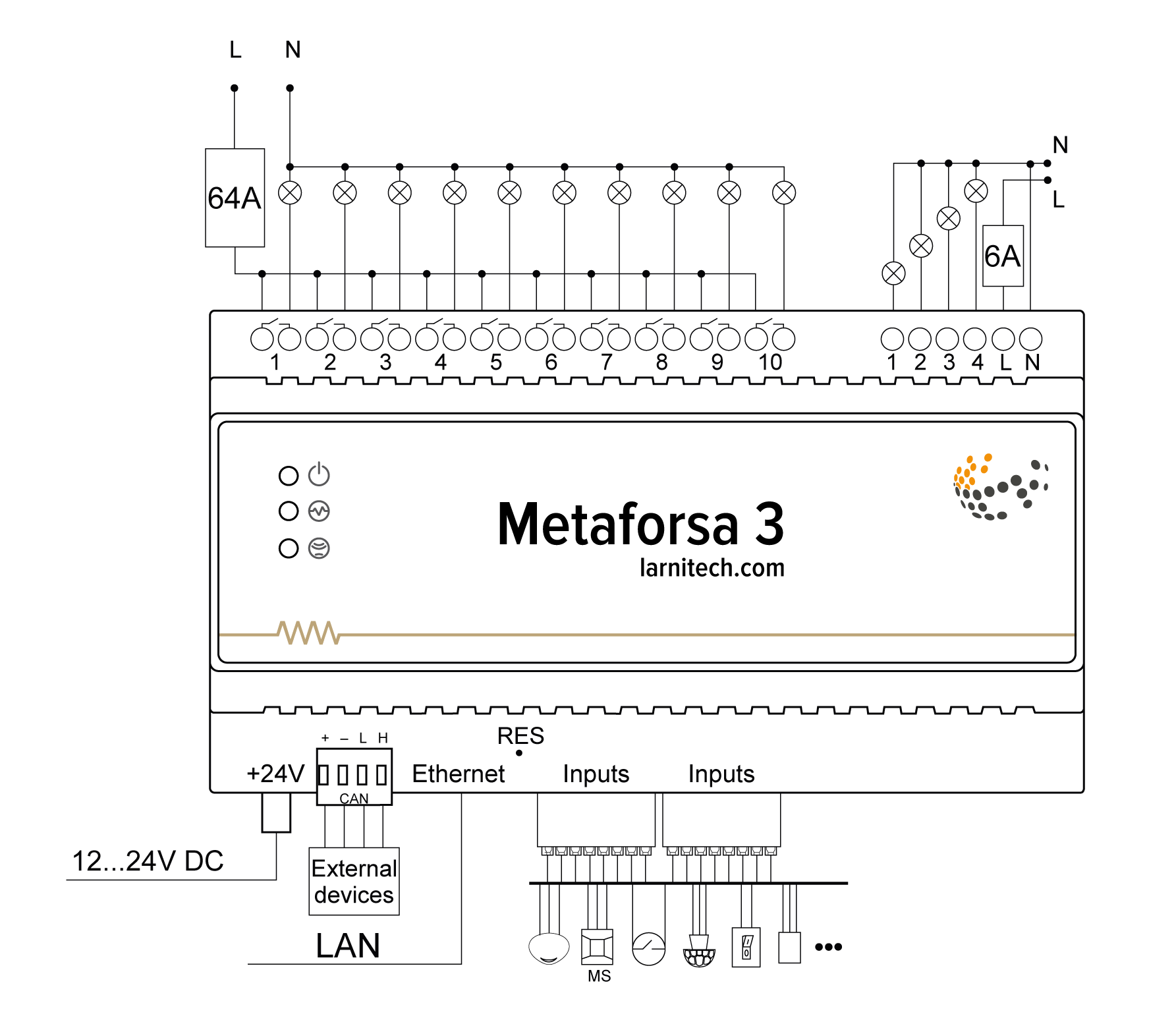

Tipični dijagram povezivanja METAFORSA 3/3.plus modula je prikazan na sl. 3.

Priključak aktuatora

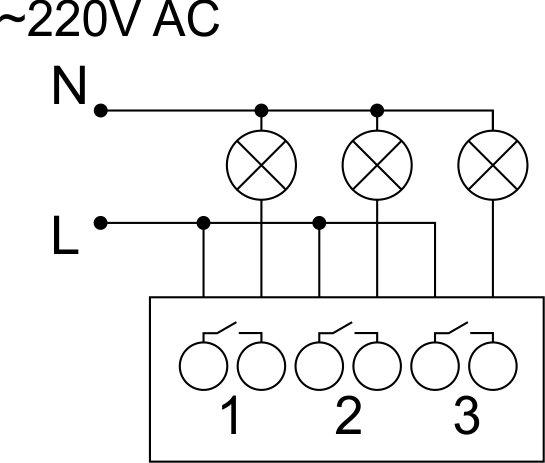

Priključak svetla/električnog kontaktora/termičnog aktuatora grejanja

Sl. 4 |

Takve aktuatore kao što su svetlo, električni kontaktor, termički aktuator za grejanje treba uključiti na bilo koji od izlaza 1 – 10, neutralnu žicu i žicu za uzemljenje treba direktno povezati na centralu. Primer povezivanja je prikazan na Sl. 4. |

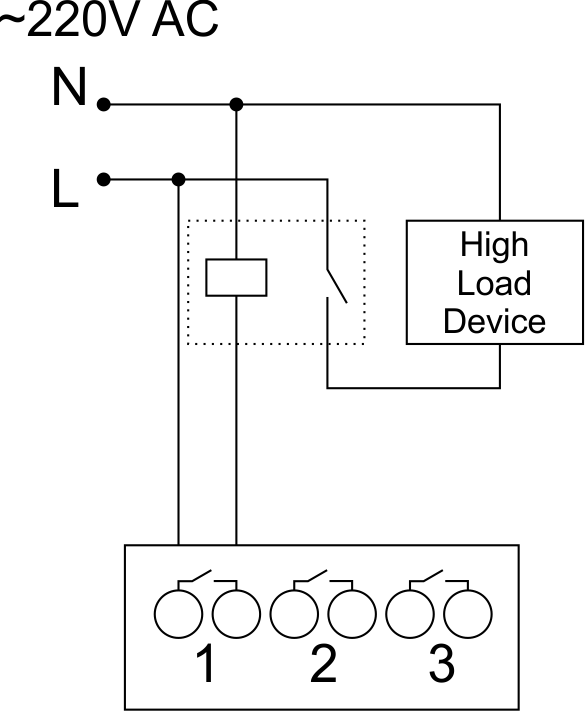

Priključivanje uređaja visokog opterećenja

|

Preporučeni kontaktori:

|

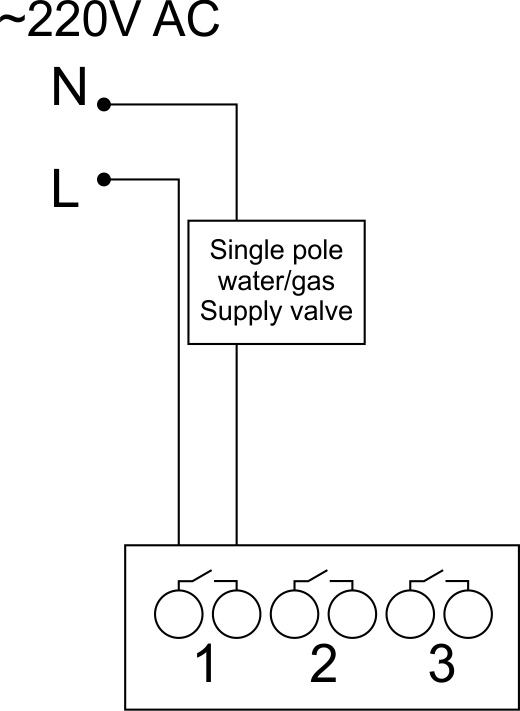

Priključak jednopolnog ventila za dovod vode/gasa

| Oprez: Pre nego što primenite napajanje na opterećenje, uverite se da je izlazna konfiguracija METAFORSA modula ispravna. Neispravna konfiguracija ili neispravno povezivanje mogu uzrokovati kvar modula i/ili kvar opreme koja je na njega povezana, pa čak i požar. | |

Sl. 5 |

Jednopolni ventil za dovod vode/gasa je povezan na bilo koji od izlaza od 1 – 10, (neutralna žica i žica za uzemljenje su povezani direktno na centralu. Primer povezivanja je prikazan na Sl.5. |

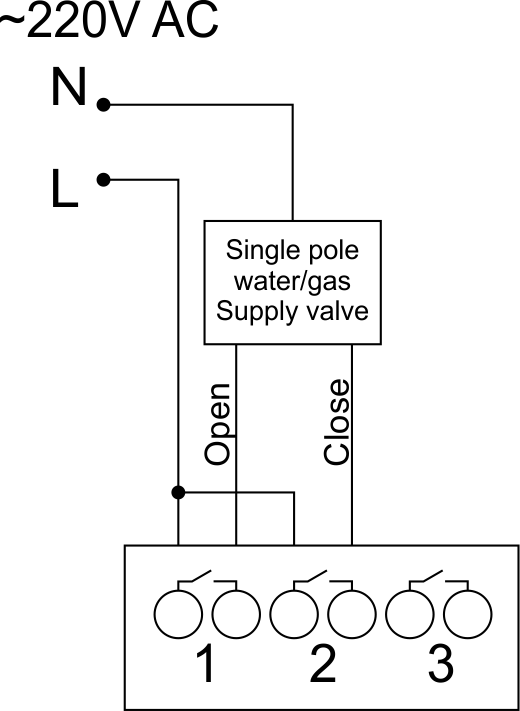

Priključak dvopolnog ventila za dovod vode/gasa

| Caution: Before applying power to the valve, it is necessary to ensure the output configuration of METAFORSA module is correct. The incorrect configuration can cause the voltage application simultaneously to both channels of the valve, which may result in the module failure and/or failure of the equipment connected to it, and even a fire. | |

Fig. 6 |

Two adjacent contact points (for example, 3, 4) are used to connect the double-pole water/gas supply valve; in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.6. |

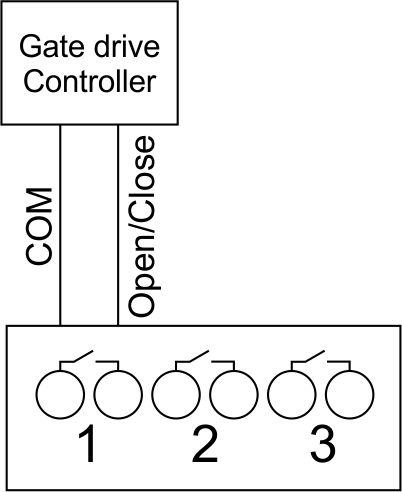

Connection of single-pole gate actuator

| Caution: Before applying power to the module, you should properly configure access to the application. The contacts incorrectly configured can result in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 7 |

Any contact point (for example, 3) is used to connect the single-pole gate drive controllers. The example of connection is shown in Fig.7. |

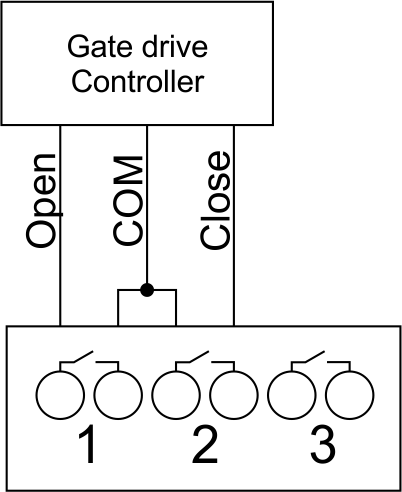

Connection of double-pole gate actuator

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 8 |

Two adjacent contact points (for example, 3, 4) should be used to connect the double-pole gate drive controller. The example of connection is shown in Fig.8. |

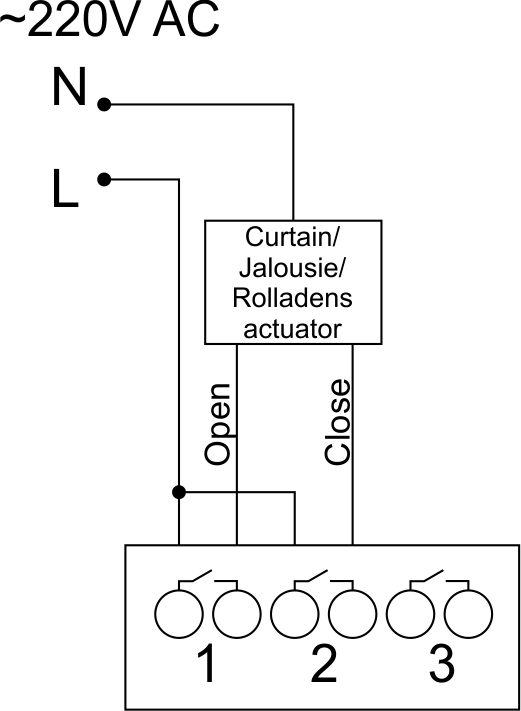

Connection of curtain/jalousie/shutter actuator with 220V force control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 9 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator, in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.9. |

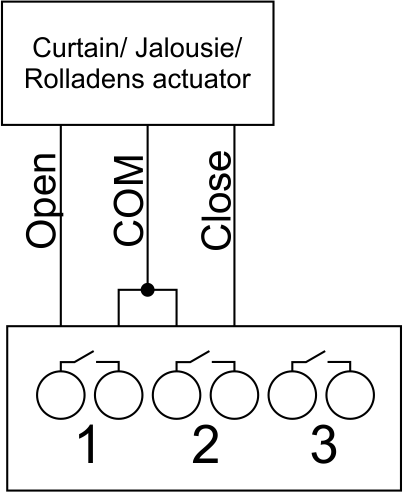

Connection of curtain/jalousie/shutter actuator with low-voltage control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 10 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator with low-voltage control. The example of connection is shown in Fig.10. |

Connection of sensing elements/switches/buttons

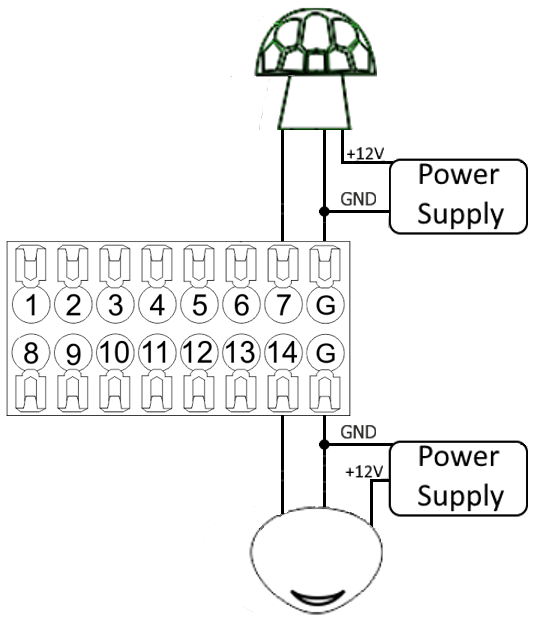

Connection of motion sensors/leakage sensors

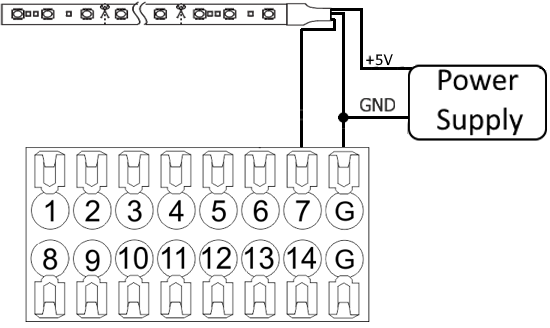

The motion sensors/leakage sensors should be connected to any free input in1-in28; in these conditions their power is connected to the contact points of +5V and GND of the relevant group. The example of connection is shown in Fig.11.

Fig. 11 connection of motion sensors/leakage sensors

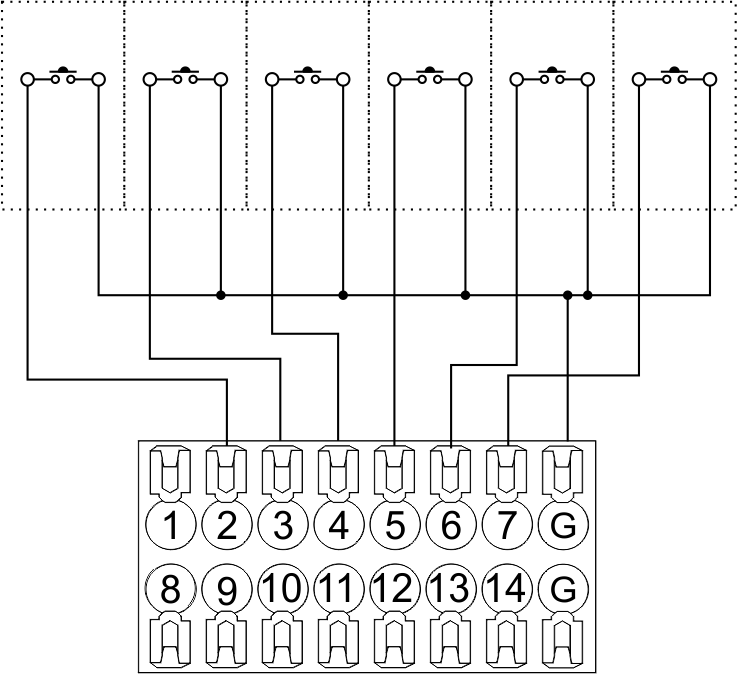

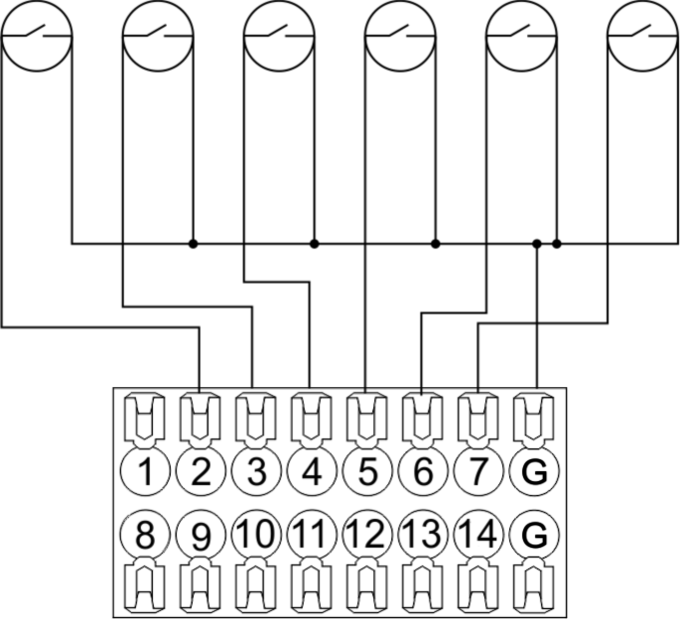

Connection of buttons/switches/magnetic reed switches

Buttons and reed switches are connected to any free input in1-in28, while their second contact point is connected to GND point of the relevant METAFORSA module group. The example of connection is shown in Fig. 12-13.

Fig. 12 connection of buttons/switching units |

Fig. 13 connection of the magnetic reed switches (window/door position sensors) |

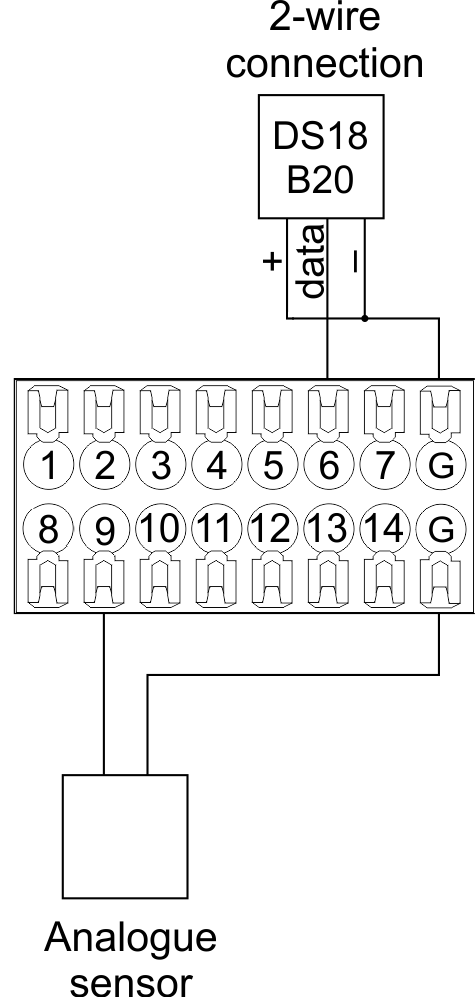

Connection of temperature sensors

Temperature sensors are connected to any free input in1-in28, while their second contact point is connected to GND point of the relevant METAFORSA module group. The example of connection is shown in Fig. 14.

Fig. 14 connection of temperature sensors

RGB connection scheme

Fig. 15 RGB connection

WS2812B connection scheme

Fig. 16 WS2812B connection

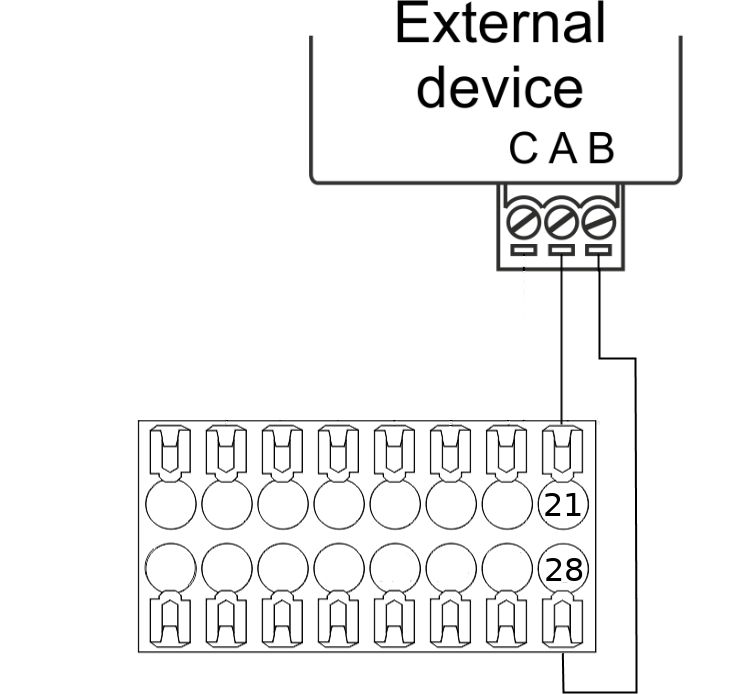

RS485 connection scheme

Fig. 17 RS485 connection

Connection of auxiliary equipment.

Expansion modules include Larnitech equipment connected through the CAN-bus. Such equipment includes: dimmers, RGB-backlit control modules, multimode sensors, etc. The equipment connected to the expansion port is defined automatically and does not require any preset tuning. Connector contact pin assignment is defined in Table 4. The example of connection is shown in Fig. 18.

|

| Caution! The 120 ohm terminating resistors should be installed at the end connectors between L and H contact points of CAN-bus. Ensure the connection is correct. The incorrect connection may cause sensor and/or module malfunction. |

Module installation and connection procedure

- Install the module in the switchboard on the DIN-rail and fix it with the special latch on the module base.

- Fasten the supply unit on the left side of the module.

- Connect the connector (4) having the noise filter pre-installed which is supplied complete with the module.

- Connect the connectors (5), (6).

- Connect the connectors (1), (2).

- Connect the connector (3).

- Apply power to the supply unit of METAFORSA module.

- Wait until the module is loaded, then configure it in accordance with the System Setup Instructions.

- Apply power to the connectors (1), (2).

- Check all equipment for proper operation.

METAFORSA module shut-off and deinstallation procedure

- De-energize the module by disconnecting the circuit breaker assembly of the load power supply and METAFORSA module supply unit. Verify the voltage is absent on the terminals (1), (2) of the connector wires and on the input terminals of the supply unit.

- Disconnect the load power supply connectors (1), (2).

- Disconnect the connector (3).

- Disconnect the connectors (4)-(6).

- Remove the module from the DIN-rail, releasing the latch at the bottom of the module base.

Hardware setup

To configure and control METAFORSA SMART HOUSE, you must install Larnitech software on your smartphone or tablet, which is available in App Store and Play Market. After installation, follow the System Setup Instructions.

Fault diagnostics and handling

The following are some possible faults and ways of fault handling. If you have any difficulty, or face the fault undeclared here, please contact the Technical Support: [1] or [support@larnitech.com]. There are also some tips in the FAQ section at our website [2].

The actuators do not operate:

- ensure the outputs are properly configured in the application (see System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.6;

- ensure the power is supplied to the input power contact , i.e. all circuit breaker assembly are ON.

- verify the operability of the connected equipment.

The module is off, indication absent:

- check the connection to 24V supply unit as shown in table 2 (contacts pin assignment);

- check the connection of the supply unit to 220V power mains, the indicator should be ON.

Network connection fault:

- ensure the Ethernet cable is properly wired and connected to the connector;

- ensure the LED status indicators are ON on the Ethernet connector;

- check the LAN configuration is correct, Ethernet cable loops are absent;

- METAFORSA module and the device you are connecting from are in the same network.

hold integer 0-10000 1-10 by default hold is the same as runtime hold is the bridging time in miliseconds, is used for gate and jalousie, lock; Example: hold=3500

The sensors do not operate:

- ensure the inputs are properly configured in the application (System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.7;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the power supply availability on the sensors;

- check the integrity of lines laid to the sensors.

The auxiliary equipment does not operate:

- check the connection is correct in accordance with table 2 and paragraph 3.8-9;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the integrity of the CAN lines, voltage supply on the modules.

HW Settings

| Name | Type, range | SUBID | Default | Description |

|---|---|---|---|---|

| runtime | integer 0-100 | 1-10 | 15 | runtime is the open/close time in seconds, is used for jalousie, gate, valve(2 pole);

|

| runtimeopen | integer 0-60000 | Blinds subId | Runtimeopen is the open time in milliseconds, is used for blinds; Example: runtimeopen=15000 | |

| runtimeclose | integer 0-60000 | Blinds subId | Runtimeclose is the close time in milliseconds, is used for blinds; Example: runtimeclose=15000 | |

| hold | integer 0-10000 | 1-10 | 500 | hold is the bridging time in milliseconds, is used for gate and jalousie (by default hold is the same as runtime for jalousie and gate), lock; Example: hold=3500 |

| def | string 'ON' | 1-10 | 'OFF' | def is the element status is set after restart, is used for lamp, heating, valve(1 pole); Example: def='ON' |

| stop | Char ‘R’ | 1-7 | – | (for 2-pole gate and blinds) If it is declared then by Stop command during the motion, the same impulse appears as it was at the beginning of the motion. Pole, an which the stop-impules is formed, is defined by the parameter Stop value. If it is ‘r’ or ‘R’ then stop-impulse is produced on the opposite to the start-impulse pole. If any other value is delcared (e.g., ‘d’ ) then the stop-impulse is on the same pole. If a Runtime passed after the beginning of the motion then the stop-impulse is not formed. Example: stop=’r’ |

| out | char[10] | 98 | 'LLLLHHHHP-' | Each char is responsible for the type of a particular channel

Example: out='LLB-G-V-W-' |

| dm | char[4] | 98 | ‘LLLL’ | Each char is responsible for the type of a particular channel

Example: dm=’skl-‘ |

| def | integer 0-250 | 11-14 | 100 | The default brightness level in case of a power reset (1..250). Example: def=250 |

| min | integer 0-100 | 11-14 | 0 | Minimum dimming level, example: min=10 |

| max | integer 0-100 | 11-14 | 100 | Maximum dimming level, example max=95 |

| start | integer 0-100 | 11-14 | 0 | The Start function is used for lamps that lack the minimal voltage to get turned on. If the set value is lower than the start value, the lamp is turned on at the start value and them the light is dimmed down to the set level. Example: start=60 |

| force | integer 0-100 | 11-14 | 10 | Time duration of the starting value (measured in milliseconds). Example: force=20 |

| runtime | integer 0-60000 | 11-14 | 1000 | Runtime is the speed of changing the brightness from ‘min’ to ‘max’ (measured in milliseconds). Example: runtime=1000 |

| offset | integer (+/- 0…39) | 39-46 | '0' | sensor values offset; For example, offset is -3.8 :

Example: hw="offset='-3.8'" |

| io | char[28] | 98 | io='KKKKKKKKKKKKKKKKKKKKKKKKKKKK' | Each char is responsible for the type of a particular channel

Example: io='KKKKKKKKKKKKKKKKKKKKKKKKKKKK' |

| hw | string | 98 | - | hw="...", where

Example: 1hw="io='4---zdd----t--' pwm_invert=1 lbn_bright=255 f=1000"

|

| Only for Metaforsa 3.plus | ||||

| cfg | string | 98 | 9600/8N1 | cfg='SPEED/BPS', where

Example: 1hw="cfg='9600/8N1'"

|

| [Protocol] | string | 98 | — | Protocol setting is described by protocol parameter. The following

protocols are supported:

Example: 1hw="cfg='9600/8N1' modbus"

|

| echo | on; off | 98 | 'off' | For settings check out and testing echo parameter can be used. Module

echo-reply can be turned on or off with the help of this parameter.Echo parameter value:

Example: 1hw="cfg='9600/8N1' echo='off'"

|

1 <item addr="349:1" auto-period="600" cfgid="197" name="Lamp 1" type="lamp"/>

2 <item addr="349:2" auto-period="600" cfgid="197" name="Lamp 2" type="lamp"/>

3 <item addr="349:3" auto-period="600" cfgid="197" name="Lamp 3" type="lamp"/>

4 <item addr="349:4" auto-period="600" cfgid="197" name="Lamp 4" type="lamp"/>

5 <item addr="349:5" auto-period="600" cfgid="197" name="Lamp 5" type="lamp"/>

6 <item addr="349:6" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

7 <automation name="Eco" temperature-level="16"/>

8 <automation name="Comfort" temperature-level="22"/>

9 <automation name="Hot" temperature-level="25"/>

10 </item>

11 <item addr="349:7" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

12 <automation name="Eco" temperature-level="16"/>

13 <automation name="Comfort" temperature-level="22"/>

14 <automation name="Hot" temperature-level="25"/>

15 </item>

16 <item addr="349:8" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

17 <automation name="Eco" temperature-level="16"/>

18 <automation name="Comfort" temperature-level="22"/>

19 <automation name="Hot" temperature-level="25"/>

20 </item>

21 <item addr="349:9" cfgid="197" name="Jalousie" sub-type="120" type="jalousie"/>

22 <item addr="349:11" auto-period="600" cfgid="197" name="Dimmer 1" type="dimmer-lamp"/>

23 <item addr="349:12" auto-period="600" cfgid="197" name="Dimmer 2" type="dimmer-lamp"/>

24 <item addr="349:13" auto-period="600" cfgid="197" name="Dimmer 3" type="dimmer-lamp"/>

25 <item addr="349:14" auto-period="600" cfgid="197" name="Dimmer 4" type="dimmer-lamp"/>

26 <item addr="349:16" cfgid="197" name="Door 1" type="door-sensor"/>

27 <item addr="349:17" cfgid="197" name="Door 2" type="door-sensor"/>

28 <item addr="349:18" cfgid="197" name="Door 3" type="door-sensor"/>

29 <item addr="349:19" cfgid="197" name="Door 4" type="door-sensor"/>

30 <item addr="349:20" cfgid="197" name="Door 5" type="door-sensor"/>

31 <item addr="349:21" cfgid="197" name="Door 6" type="door-sensor"/>

32 <item addr="349:22" cfgid="197" name="Door 7" type="door-sensor"/>

33 <item addr="349:23" cfgid="197" name="Door 8" type="door-sensor"/>

34 <item addr="349:24" cfgid="197" name="Door 9" type="door-sensor"/>

35 <item addr="349:25" cfgid="197" name="Door 10" type="door-sensor"/>

36 <item addr="349:26" cfgid="197" name="Door 11" type="door-sensor"/>

37 <item addr="349:27" cfgid="197" name="Door 12" type="door-sensor"/>

38 <item addr="349:28" cfgid="197" name="Door 13" type="door-sensor"/>

39 <item addr="349:29" cfgid="197" name="Door 14" type="door-sensor"/>

40 <item addr="349:30" cfgid="197" name="Door 15" type="door-sensor"/>

41 <item addr="349:31" cfgid="197" name="Door 16" type="door-sensor"/>

42 <item addr="349:32" cfgid="197" name="Door 17" type="door-sensor"/>

43 <item addr="349:33" cfgid="197" name="Door 18" type="door-sensor"/>

44 <item addr="349:34" cfgid="197" name="Door 19" type="door-sensor"/>

45 <item addr="349:35" cfgid="197" name="Door 20" type="door-sensor"/>

46 <item addr="349:36" cfgid="197" name="Door 21" type="door-sensor"/>

47 <item addr="349:37" cfgid="197" name="Door 22" type="door-sensor"/>

48 <item addr="349:38" cfgid="197" name="Door 23" type="door-sensor"/>

49 <item addr="349:39" cfgid="197" name="Door 24" type="door-sensor"/>

50 <item addr="349:40" cfgid="197" name="Door 24" type="door-sensor"/>

51 <item addr="349:41" cfgid="197" name="Door 25" type="door-sensor"/>

52 <item addr="349:43" cfgid="197" name="IR receiver" type="ir-receiver"/>

53 <item addr="349:44" cfgid="197" name="RS485" type="com-port"/>

54 <item addr="349:90" cfgid="197" name="Current" system="yes" type="current-sensor"/>

55 <item addr="349:95" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

56 <item addr="349:96" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

57 <item addr="349:97" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

58 <item addr="349:98" cfgid="197" hw="out='LLLLLHHHB-' dm='LLLL' io='KKKKKKKKKKKKKKKKKKKKUKKKKKK-'" logic-ver="19" name="Temperature" sn="2533726919" system="yes" type="temperature-sensor"/>

59 <item addr="349:100" cfgid="197" name="RS232" type="com-port"/>