Difference between revisions of "Metaforsa 3/3.plus/da"

(Created page with "*placer sensoren og aktuatorerne (hvis de ikke er forudinstalleret), indstil sensorerne og aktuatorerne; *placer modulet og strømforsyningen.") Tags: Mobile web edit Mobile edit |

(Created page with "'''Bemærk: Modulet skal installeres i nærheden af strømforsyningsspændingskilden.'''") Tags: Mobile web edit Mobile edit |

||

| Line 296: | Line 296: | ||

| − | ''' | + | '''Bemærk: Modulet skal installeres i nærheden af strømforsyningsspændingskilden.''' |

Revision as of 08:21, 8 April 2024

| MF3/MF3.plus | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

Introduktion

METAFORSA SMART HOUSE Installationsmanual beskriver proceduren for installation, montering, betjening og indstilling. Mens du arbejder med systemet, skal du nøje overholde alle kravene i denne manual. Manglende overholdelse kan resultere i beskadigelse af enheden, dens fejl, elektrisk stød, brand og andet nedfald. Producenten forbeholder sig retten til at foretage ændringer i denne manual uden forudgående varsel. Denne manual er en integreret del af systemet og forbliver hos slutbrugeren.

Funktioner

- 10 universelle udgange understøtter:

- Lys

- NC/NO varmeventiler

- Persienner

- 1 eller 2-polede porte

- 1 eller 2-polede ventiler

- NC/NO låse

- Blæserkonvektorer

- 4 dæmpningsudgange

- 28 indgange, der understøtter:

- Knapper

- LED-knapper

- Switcher

- Reed-kontakter

- Lækagesensorer

- Bevægelsesdetektorer

- Temperatursensorer

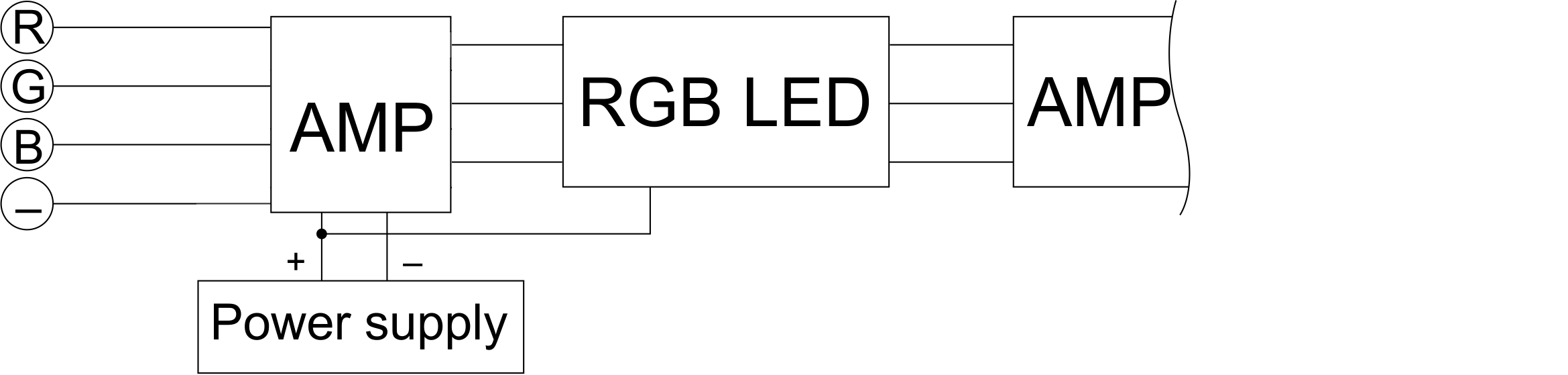

- LED strips

- 3-4-5 kanals RGB-strimler

- WS2812B strimler

- RS485-enheder (kun til Metaforsa 3.plus)

- Forlængerport

- Relæer med AgSnO2-kontakter klassificeret til 80A 20ms startstrøm

- Skyforbindelse og kontrol af alle hussystemer

- Stemmestyring (Siri, Alexa, Google Home)

Sikkerhedskrav

For at undgå risikoen for brand, elektrisk stød, beskadigelse af systemet og/eller personskade, skal installationen og monteringen af systemet udføres i overensstemmelse med instruktionerne nedenfor:

- alle tilslutningsarbejder skal udføres uden strøm;

- brug passende værktøj og personlig beskyttelse mod elektrisk stød;

- brug ikke beskadigede kabler, ledninger og stik;

- undgå foldning af kabler og ledninger;

- undgå at klemme eller knække kabler og ledninger ved at anvende for stor kraft. Ellers kan indvendige ledere af kablet og ledningerne blive strippet eller knækket;

- brug ikke stikkontakten med dårlige kontakter til at forbinde;

- overskrid ikke grænsen for belastningsparametre angivet i denne manual;

- forsyningsledernes ledningssektion er underlagt specifikationerne for strømtæthedsgrænse, isoleringstype og ledningsmateriale. Lyssektion kan resultere i kabeloverophedning og brand.

Når du arbejder med systemet efter spændingsforsyning ALDRIG:

- foretag tilslutning/frakobling af stik;

- åbne moduler og sensorer.

Systemkonfiguration og formål

Formål med systemet

METAFORSA SMART HOUSE er en færdiglavet løsning til automatisering af bolig- og erhvervslokaler, hotelkomplekser, som indeholder de mest eftertragtede funktioner i Smart House.

Enheden har 10 kontrolkanaler, 4 dæmpningskanaler og 28 indgangskanaler antal.

| Universaludgange kan bruges til at styre: | Universalindgange giver dig mulighed for at tilslutte: |

|---|---|

| Belysning | Knapper/LED-knapper/omskiftningsenheder |

| Stikstik | Magnetiske reed-kontakter |

| Gulvvarme | Lækagesensorer |

| Gardin | Bevægelsesdetektorer |

| Portaktuatorer | Temperaturfølere |

| Vandforsyning | LED strips/3-4-5 kanals RGB strips/WS2812B strips |

| Varmeventiler | RS485-enheder* |

* – Kun til Metaforsa 3.plus

Udvidelsesport

Udvidelsesporten giver dig mulighed for at opgradere systemet ved at tilslutte ekstraudstyr, såsom styremodulet til LED-belysning, dæmpning, måleenheder og andre elementer.

Pakken, som er fuldstændig klar til at installere, inkluderer den grundlæggende hardware og software.

Pakkens indhold

Pakken leveres som standard med:

| Mainframe METAFORSA 3/3.plus | 1 stk |

| Strømforsyningsenhed MEANWELL DR-15-12 | 1 stk |

| Bevægelsessensor CW-MSD | 3 stk |

| Lækagesensor FW-WL.B | 2 stk |

| Temperaturfølsomt element FW-TS | 4 stk |

| Magnetisk reed-kontakt (vindues-/dørpositionssensor) | 4 stk |

| Ethernet-kabel støjfilter | 1 stk |

| Strømforsyningsledning | 1 stk |

Grundlæggende tekniske specifikationer for systemet

De grundlæggende specifikationer og egenskaber for modulet METAFORSA 3/3.plus er vist i tabel 1

| Specifikation | Betyder |

|---|---|

| Udgangsporte | |

| Antal skiftede kanaler | 10 |

| Antal skiftede grupper | 10 |

| Antal dæmpningskanaler | 4 |

| Kommuteringsspænding | 0-250 V AC/DC |

| Spidsbelastning (én kanal) | 16A |

| Spidsbelastning (enhed) | 160A |

| Maks. belastning pr. dæmpningskanal | 0,5A (110W ved 220V) |

| Lysdæmper type | MOSFET |

| Lysdæmper belastningstype | R,C |

| Lysdæmpningstype | bagkant |

| Strømforsyningskabeltilslutningstype | stik |

| Tilladt sektion af strømforsyningskablet til tilslutning i stikket: enkeltlederkabel flerlederkabel tilsluttet flerlederkabel |

0,5 … 4mm2 0,5 … 4mm2 0,5 … 2,5 mm2 |

| Indgangsporte | |

| Antal diskrete input | 28 |

| Maksimal strømstyrke på jævnspændingsstikkene | 5 mA* |

| Andet | |

| Omgivelsestemperatur i drift | 0 … +45°С |

| Opbevarings-/transporttemperatur | -10 … +50°С |

| Tilladt luftfugtighed | 0 … 95 % (ikke-kondenserende) |

| Strømforsyning | 11,5 … 27,5 V DC 24V, 0,75A anbefales |

| Maksimal efterspørgsel | 0,5A |

| Tilgængelige grænseflader | Ethernet, CAN |

| Bustype | CAN (4-leder) |

| CAN (4-leder) | 800 m** (parsnoet CAT5e) |

| CAN ledningstype | FTP Cat 5E |

| CAN-forbindelsestype | Stik |

| Maksimal længde for digital linje | 30 m |

| Digital line wirde type | UTP/FTP Cat 5E |

| LAN maksimal længde | 100 m |

| LAN-ledningstype | UTP/FTP Cat 5E |

| LAN-forbindelsestype | Stik RJ-45 |

| RS485 porte antal | 1*** |

| Dataoverførselshastighed | 1200-115200 b/s*** |

| Dimensionsspecifikationer | 9U, 156x90x58 mm |

| Skalmateriale | ABS |

| Turhus | IP40 |

| Installationstype for udstyr | DIN-skinne (EN 60715) |

| Vægt | 400 g |

* – Udgangskanaler bør kun tilsluttes ved hjælp af en forstærker, der bruger 5V PWM-signal fra IO-udgang som input

** – installation af yderligere strømforsyningsenheder er påkrævet for lange linjer; den maksimale længde af ledningen kan reduceres af forskellige interferensfaktorer

*** – Kun til Metaforsa 3.plus

Systemets generel struktur

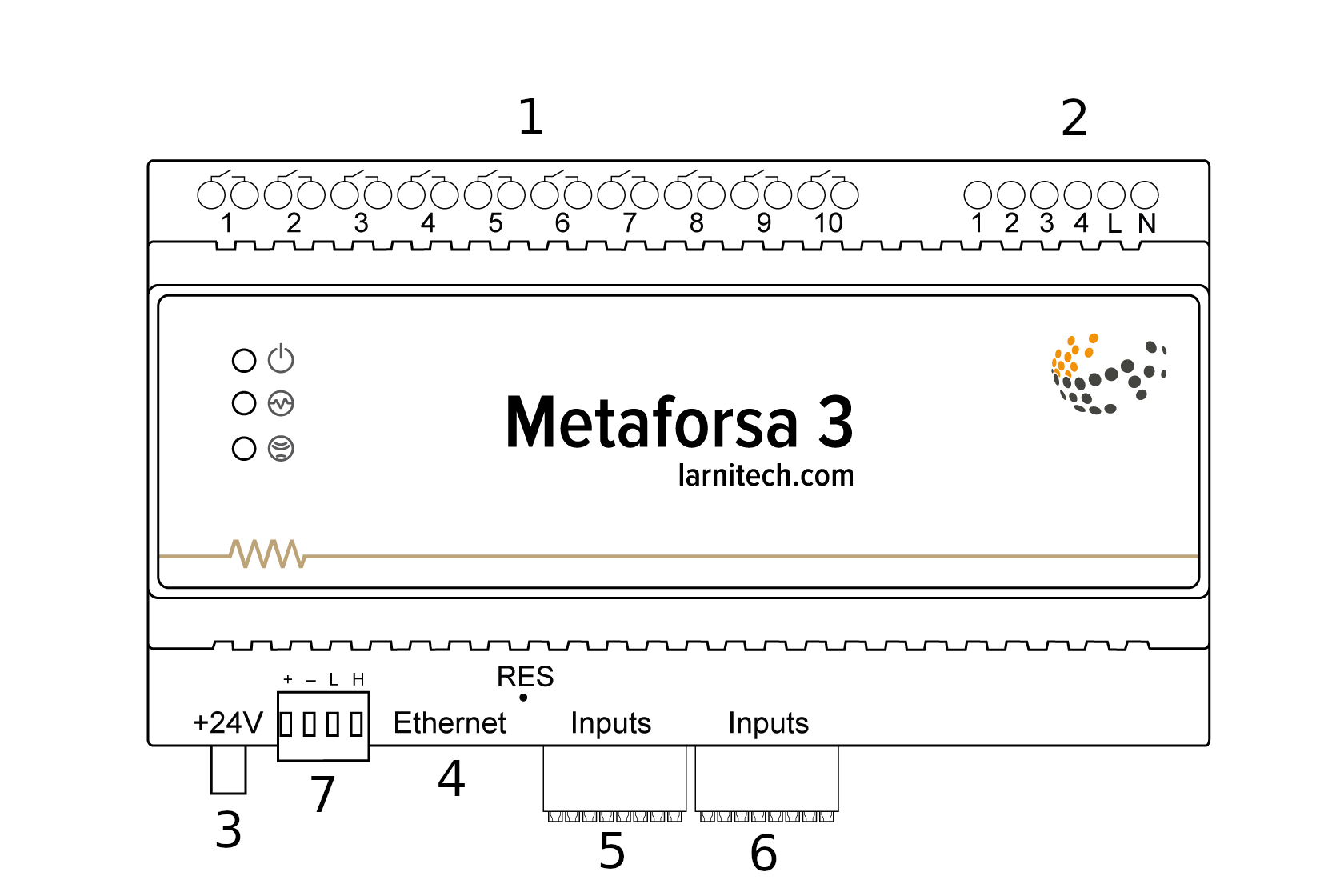

Modulets generelle visning er vist i fig. 1

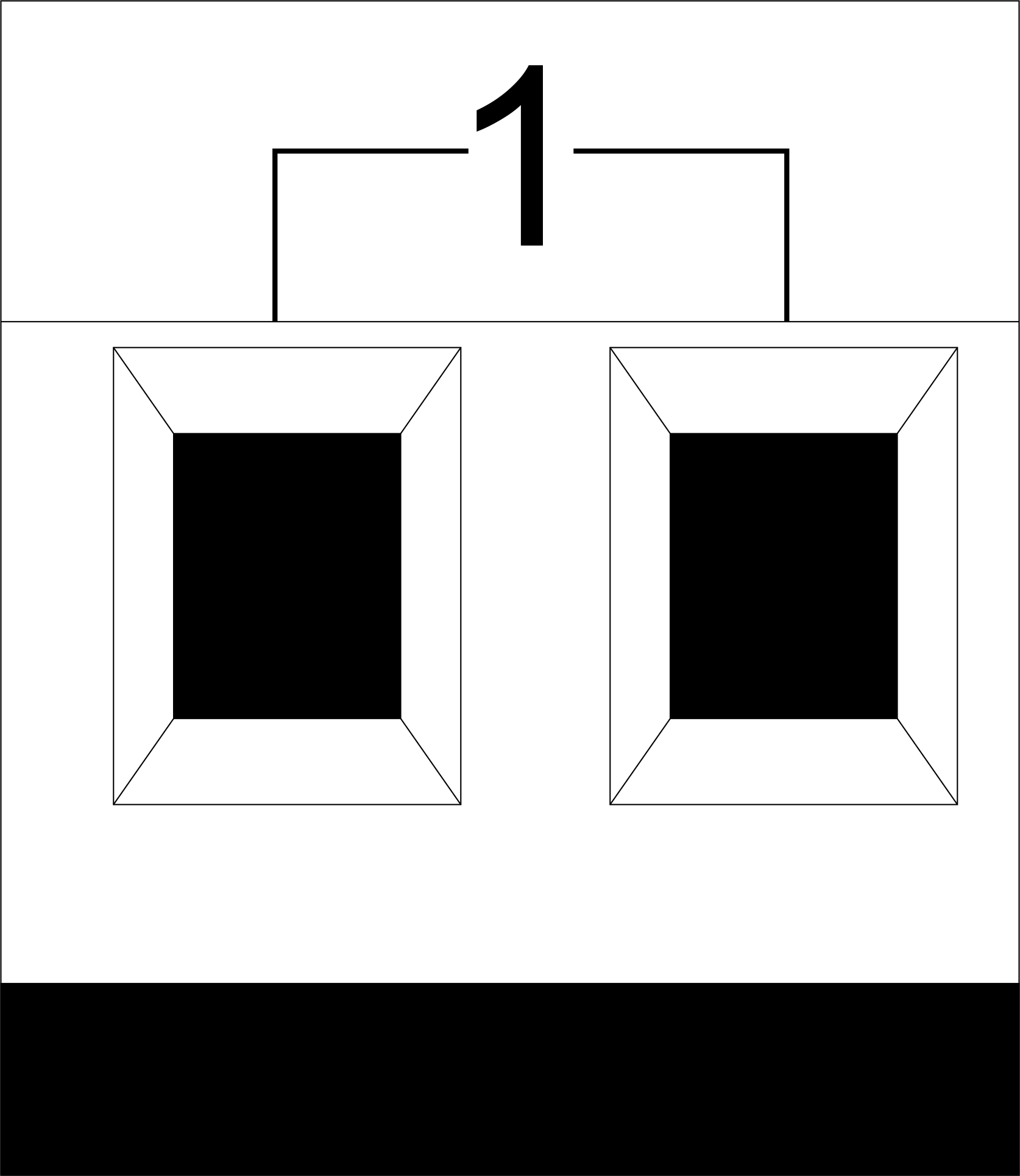

| 1 | — stik til belastningsanvendelse |

| 2 | — stik til dæmpning af lamper |

| 3 | — strømstik |

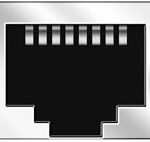

| 4 | — Ethernet-netværksstik |

| 5-6 | — stik til universelle ind-/udgangskanaler |

| 7 | — stik til udvidelsesmodul. |

Oversigt over METAFORSA-enhedens eksterne stik:

Øverst på kabinettet (fig. 1) er der:

- stik (1) — Enhedsforbindelse;

- stik (2) — Tilslutning af dæmpende lamper;

I bunden af kabinettet (fig. 1) er der:

- stik (3) — modulstrømforsyningsforbindelse;

- stik (4) — Ethernet-netværksforbindelse;

- stik (5-6) — universel ind-/udgangskanalforbindelse - knapper, reed-kontakter, LED-knapper, lækagesensorer, bevægelsessensorer, temperatursensorer, LED-strips, 3-4-5 kanals RGB-strips, WS2812B-strips, RS485-enheder ( Kun til Metaforsa 3.plus);

- stik (7) — udvidelsesmodultilslutning.

Den fysiske konfiguration og tildeling af kontaktpunkter for hvert stik er vist i tabel 2.

| Kontakt | Kontakt | Opgave |

|---|---|---|

|

1-10 | Belastning (lyslamper, termiske aktuatorer osv.) |

| D1-4, L, N | Belastningsanvendelse (dæmpende lamper) | |

| Enhedsstatusindikatorer | Modulstatusindikatorerne er beskrevet i tabel 3 | |

|

+24V GND |

+24V — modulstrømforsyning med en ekstern 24 V strømforsyning GND — fælles |

|

RJ45 | Stik til LAN-forbindelse |

| In1-14, In15-28 GND | Tilslutning af styreenheder (knapper, LED-knapper, magnetiske reed-kontakter, bevægelsesdetektorer, lækagesensorer, temperatursensorer osv.): In1 … In28 — logiske indgange GND — fælles | |

|

VCC GND L H |

Eksterne moduler tilslutning til CAN-bus VСС — 24V udgang til eksterne enheder strømforsyning GND — almindelig L — CAN-L databus H — CAN-H databus |

| Indicator | Status | Description |

|---|---|---|

| Power | Power | |

| Power not available | ||

| Activity | Data communication | |

| Data communication not available | ||

| Error | No errors | |

| Communication error | ||

| Module overheat | ||

| Dimmer outputs module overload | ||

| Absence of power on dimmers, if in configuration |

Systeminstallation og montering

Før du tilslutter systemet, skal du:

- placer sensoren og aktuatorerne (hvis de ikke er forudinstalleret), indstil sensorerne og aktuatorerne;

- placer modulet og strømforsyningen.

Bemærk: Modulet skal installeres i nærheden af strømforsyningsspændingskilden.

- The power of circuit breaker assembly must comply with the load capacity;

- Nothing else than the phase conductors can be connected to the module, the neutral wire is connected separately.

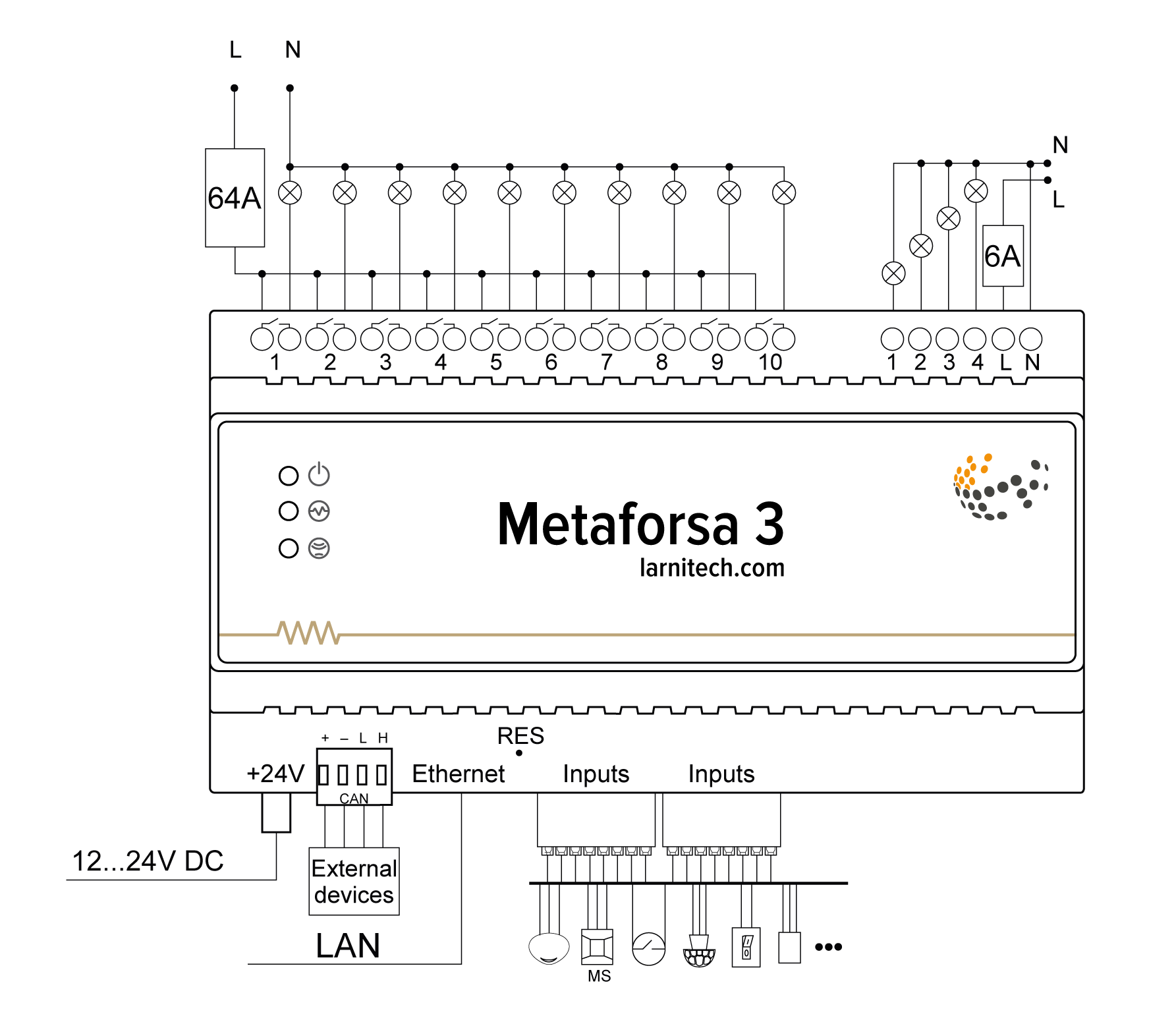

Typical diagram of METAFORSA 3/3.plus module connection is shown in fig. 3.

Connection of the actuators

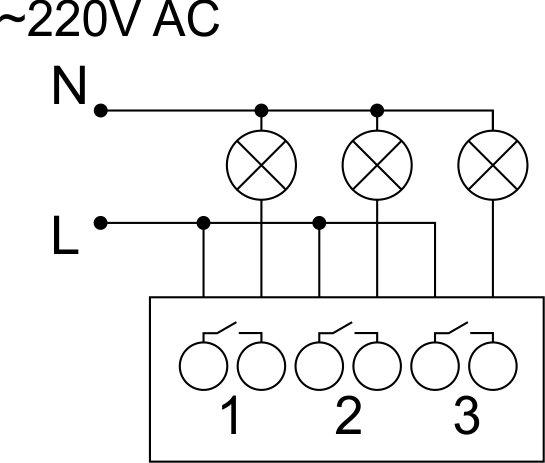

Connection of the lights/electric contactor/heating thermal actuator

Fig. 4 |

Such actuators as light, electric contactor, heating thermal actuator should be switched on any of the outputs 1 – 10, the neutral wire and the ground wire should be connected directly to the switchboard. The example of connection is shown in Fig.4. |

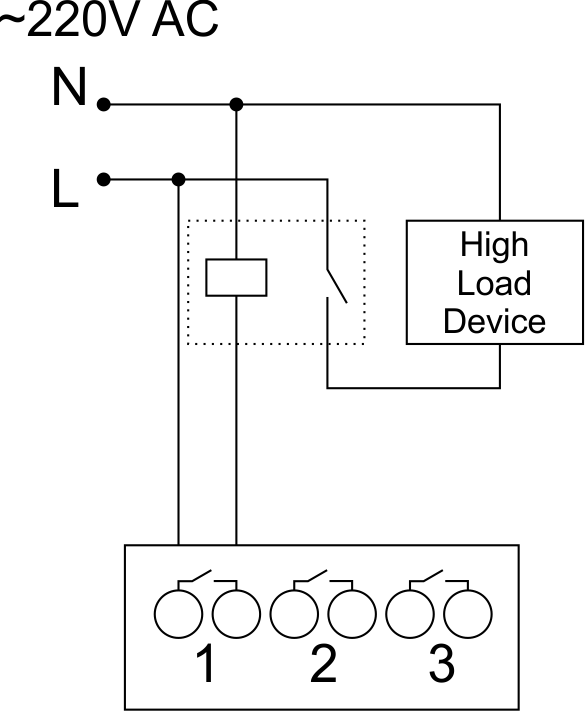

Connection of high load device

|

Recomended contactors:

|

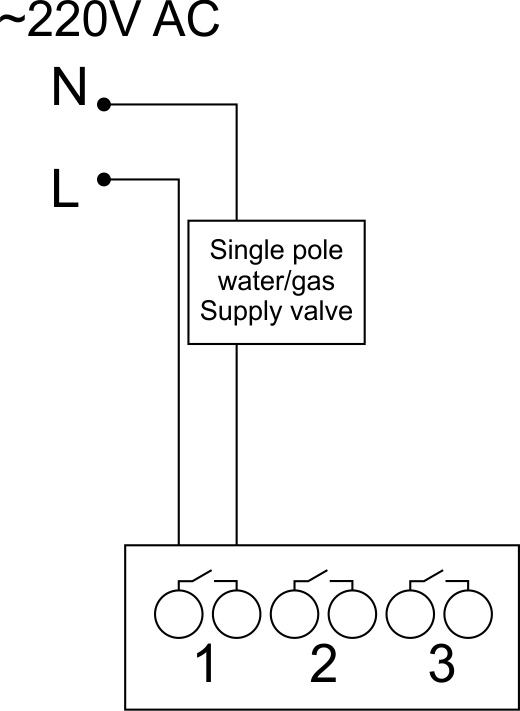

Connection of single-pole water/gas supply valve

| Caution: Before applying power to the load, make sure that the output configuration of METAFORSA module is correct. The incorrect configuration or incorrect connection can cause the module failure and/or failure of the equipment connected to it, and even a fire. | |

Fig. 5 |

The single pole water/gas supply valve is connected to any of the outputs of 1 – 10, the (neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.5. |

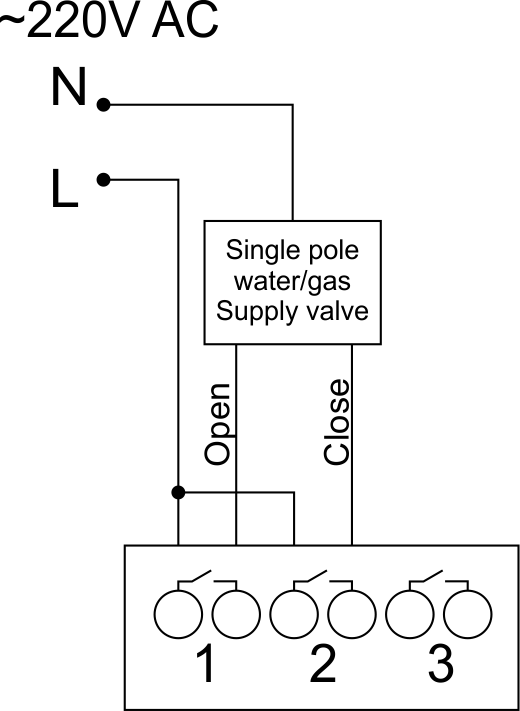

Connection of double-pole water/gas supply valve

| Caution: Before applying power to the valve, it is necessary to ensure the output configuration of METAFORSA module is correct. The incorrect configuration can cause the voltage application simultaneously to both channels of the valve, which may result in the module failure and/or failure of the equipment connected to it, and even a fire. | |

Fig. 6 |

Two adjacent contact points (for example, 3, 4) are used to connect the double-pole water/gas supply valve; in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.6. |

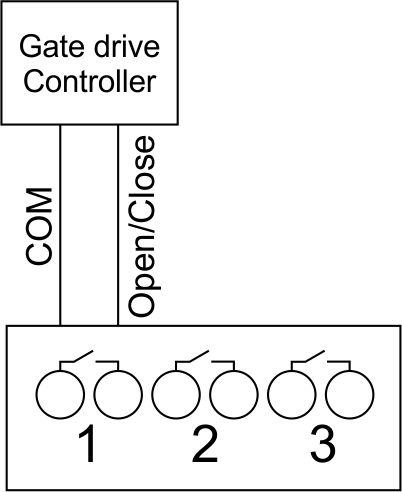

Connection of single-pole gate actuator

| Caution: Before applying power to the module, you should properly configure access to the application. The contacts incorrectly configured can result in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 7 |

Any contact point (for example, 3) is used to connect the single-pole gate drive controllers. The example of connection is shown in Fig.7. |

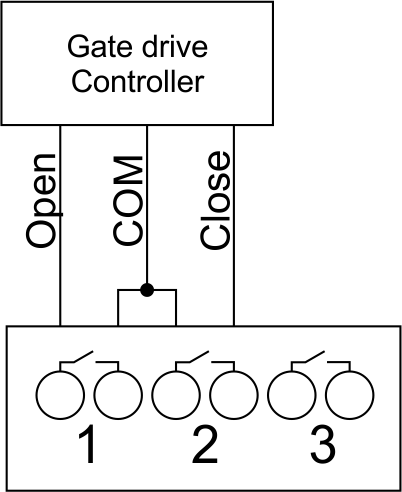

Connection of double-pole gate actuator

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 8 |

Two adjacent contact points (for example, 3, 4) should be used to connect the double-pole gate drive controller. The example of connection is shown in Fig.8. |

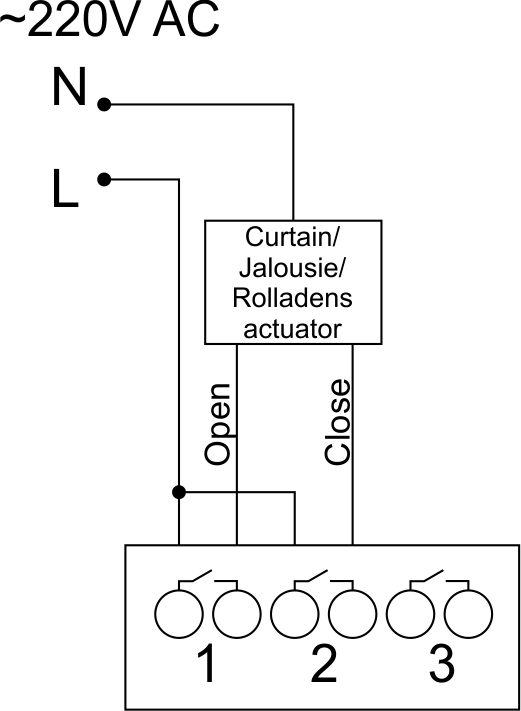

Connection of curtain/jalousie/shutter actuator with 220V force control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 9 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator, in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.9. |

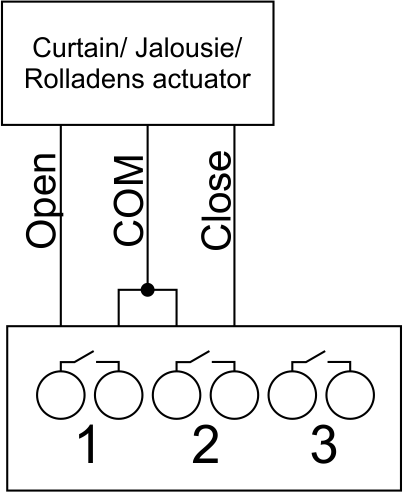

Connection of curtain/jalousie/shutter actuator with low-voltage control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 10 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator with low-voltage control. The example of connection is shown in Fig.10. |

Connection of sensing elements/switches/buttons

Connection of motion sensors/leakage sensors

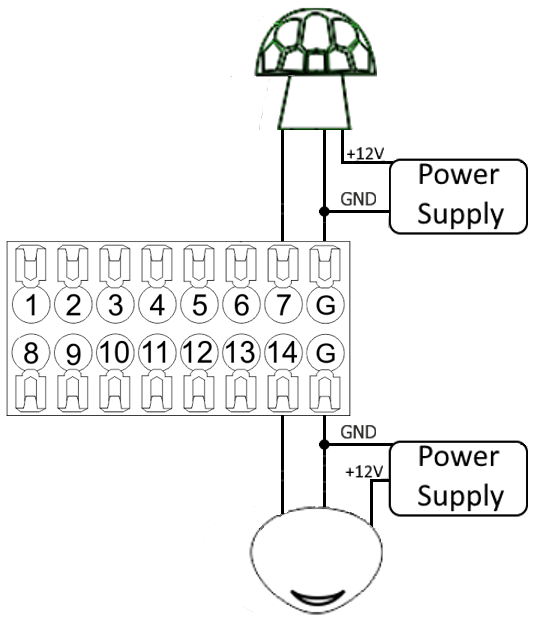

The motion sensors/leakage sensors should be connected to any free input in1-in28; in these conditions their power is connected to the contact points of +5V and GND of the relevant group. The example of connection is shown in Fig.11.

Fig. 11 connection of motion sensors/leakage sensors

Connection of buttons/switches/magnetic reed switches

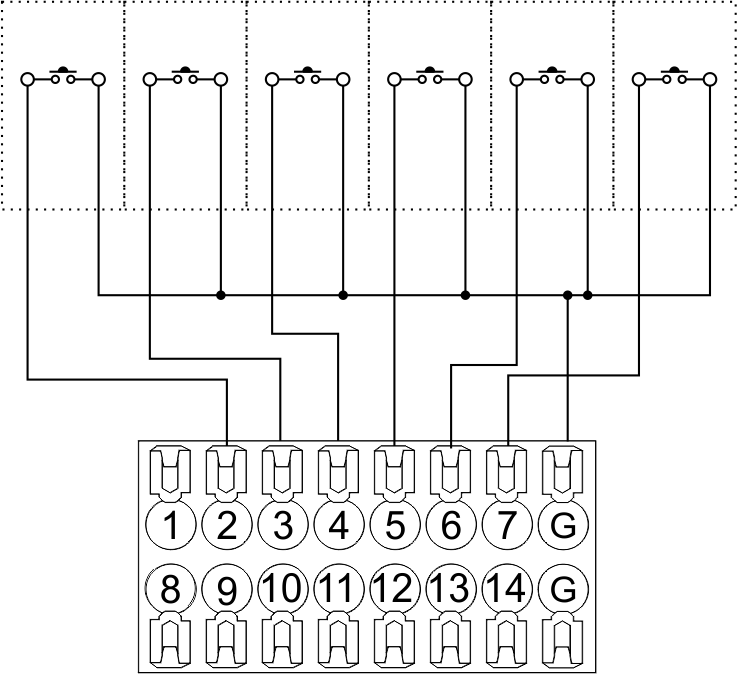

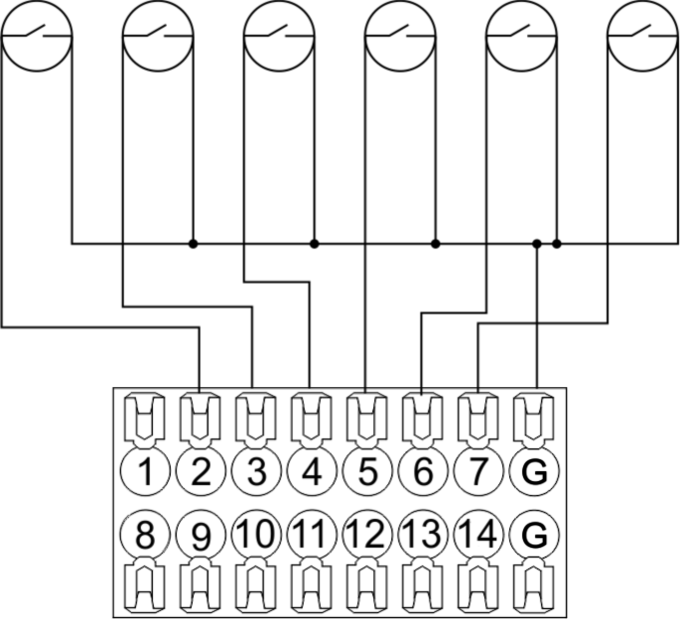

Buttons and reed switches are connected to any free input in1-in28, while their second contact point is connected to GND point of the relevant METAFORSA module group. The example of connection is shown in Fig. 12-13.

Fig. 12 connection of buttons/switching units |

Fig. 13 connection of the magnetic reed switches (window/door position sensors) |

Connection of temperature sensors

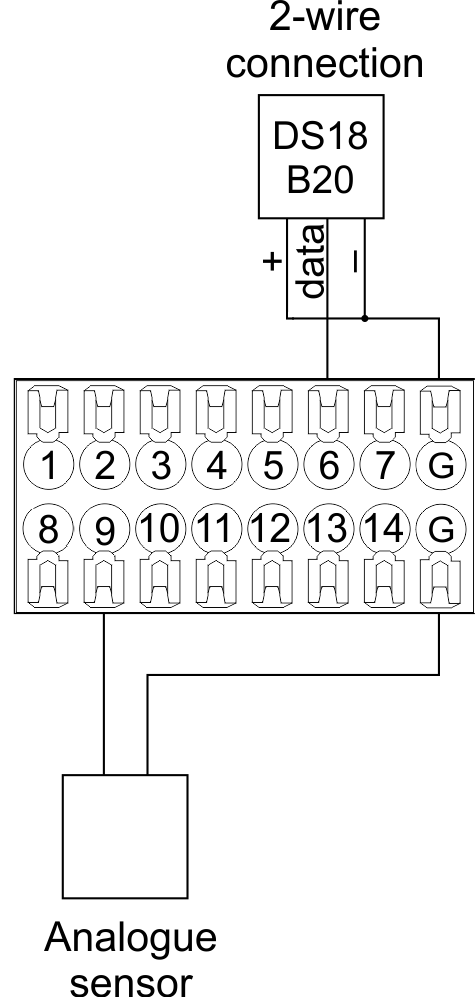

Temperature sensors are connected to any free input in1-in28, while their second contact point is connected to GND point of the relevant METAFORSA module group. The example of connection is shown in Fig. 14.

Fig. 14 connection of temperature sensors

RGB connection scheme

Fig. 15 RGB connection

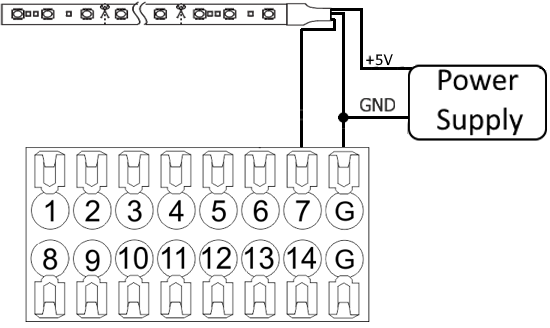

WS2812B connection scheme

Fig. 16 WS2812B connection

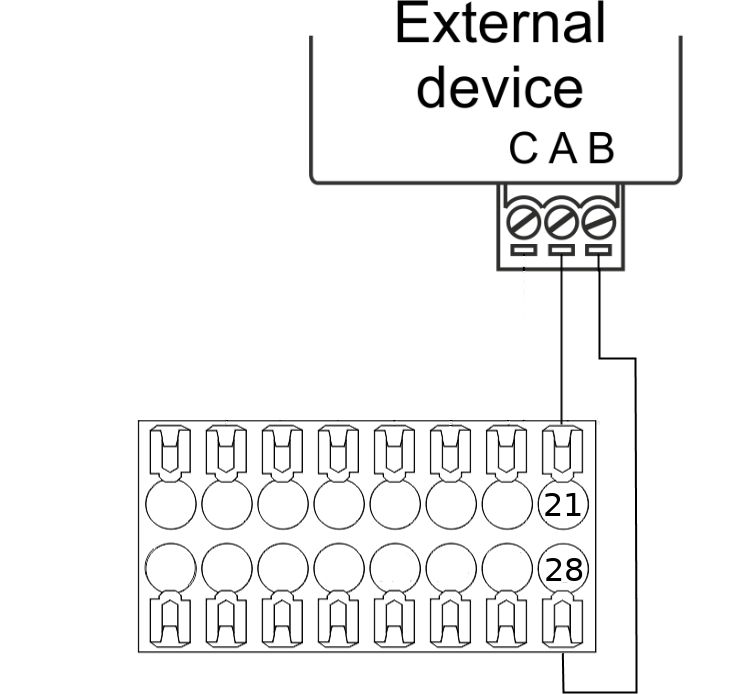

RS485 connection scheme

Fig. 17 RS485 connection

Connection of auxiliary equipment.

Expansion modules include Larnitech equipment connected through the CAN-bus. Such equipment includes: dimmers, RGB-backlit control modules, multimode sensors, etc. The equipment connected to the expansion port is defined automatically and does not require any preset tuning. Connector contact pin assignment is defined in Table 4. The example of connection is shown in Fig. 18.

|

| Caution! The 120 ohm terminating resistors should be installed at the end connectors between L and H contact points of CAN-bus. Ensure the connection is correct. The incorrect connection may cause sensor and/or module malfunction. |

Module installation and connection procedure

- Install the module in the switchboard on the DIN-rail and fix it with the special latch on the module base.

- Fasten the supply unit on the left side of the module.

- Connect the connector (4) having the noise filter pre-installed which is supplied complete with the module.

- Connect the connectors (5), (6).

- Connect the connectors (1), (2).

- Connect the connector (3).

- Apply power to the supply unit of METAFORSA module.

- Wait until the module is loaded, then configure it in accordance with the System Setup Instructions.

- Apply power to the connectors (1), (2).

- Check all equipment for proper operation.

METAFORSA module shut-off and deinstallation procedure

- De-energize the module by disconnecting the circuit breaker assembly of the load power supply and METAFORSA module supply unit. Verify the voltage is absent on the terminals (1), (2) of the connector wires and on the input terminals of the supply unit.

- Disconnect the load power supply connectors (1), (2).

- Disconnect the connector (3).

- Disconnect the connectors (4)-(6).

- Remove the module from the DIN-rail, releasing the latch at the bottom of the module base.

Hardware setup

To configure and control METAFORSA SMART HOUSE, you must install Larnitech software on your smartphone or tablet, which is available in App Store and Play Market. After installation, follow the System Setup Instructions.

Fault diagnostics and handling

The following are some possible faults and ways of fault handling. If you have any difficulty, or face the fault undeclared here, please contact the Technical Support: [1] or [support@larnitech.com]. There are also some tips in the FAQ section at our website [2].

The actuators do not operate:

- ensure the outputs are properly configured in the application (see System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.6;

- ensure the power is supplied to the input power contact , i.e. all circuit breaker assembly are ON.

- verify the operability of the connected equipment.

The module is off, indication absent:

- check the connection to 24V supply unit as shown in table 2 (contacts pin assignment);

- check the connection of the supply unit to 220V power mains, the indicator should be ON.

Network connection fault:

- ensure the Ethernet cable is properly wired and connected to the connector;

- ensure the LED status indicators are ON on the Ethernet connector;

- check the LAN configuration is correct, Ethernet cable loops are absent;

- METAFORSA module and the device you are connecting from are in the same network.

hold integer 0-10000 1-10 by default hold is the same as runtime hold is the bridging time in miliseconds, is used for gate and jalousie, lock; Example: hold=3500

The sensors do not operate:

- ensure the inputs are properly configured in the application (System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.7;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the power supply availability on the sensors;

- check the integrity of lines laid to the sensors.

The auxiliary equipment does not operate:

- check the connection is correct in accordance with table 2 and paragraph 3.8-9;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the integrity of the CAN lines, voltage supply on the modules.

HW Settings

| Name | Type, range | SUBID | Default | Description |

|---|---|---|---|---|

| runtime | integer 0-100 | 1-10 | 15 | runtime is the open/close time in seconds, is used for jalousie, gate, valve(2 pole);

|

| runtimeopen | integer 0-60000 | Blinds subId | Runtimeopen is the open time in milliseconds, is used for blinds; Example: runtimeopen=15000 | |

| runtimeclose | integer 0-60000 | Blinds subId | Runtimeclose is the close time in milliseconds, is used for blinds; Example: runtimeclose=15000 | |

| hold | integer 0-10000 | 1-10 | 500 | hold is the bridging time in milliseconds, is used for gate and jalousie (by default hold is the same as runtime for jalousie and gate), lock; Example: hold=3500 |

| def | string 'ON' | 1-10 | 'OFF' | def is the element status is set after restart, is used for lamp, heating, valve(1 pole); Example: def='ON' |

| stop | Char ‘R’ | 1-7 | – | (for 2-pole gate and blinds) If it is declared then by Stop command during the motion, the same impulse appears as it was at the beginning of the motion. Pole, an which the stop-impules is formed, is defined by the parameter Stop value. If it is ‘r’ or ‘R’ then stop-impulse is produced on the opposite to the start-impulse pole. If any other value is delcared (e.g., ‘d’ ) then the stop-impulse is on the same pole. If a Runtime passed after the beginning of the motion then the stop-impulse is not formed. Example: stop=’r’ |

| out | char[10] | 98 | 'LLLLHHHHP-' | Each char is responsible for the type of a particular channel

Example: out='LLB-G-V-W-' |

| dm | char[4] | 98 | ‘LLLL’ | Each char is responsible for the type of a particular channel

Example: dm=’skl-‘ |

| def | integer 0-250 | 11-14 | 100 | The default brightness level in case of a power reset (1..250). Example: def=250 |

| min | integer 0-100 | 11-14 | 0 | Minimum dimming level, example: min=10 |

| max | integer 0-100 | 11-14 | 100 | Maximum dimming level, example max=95 |

| start | integer 0-100 | 11-14 | 0 | The Start function is used for lamps that lack the minimal voltage to get turned on. If the set value is lower than the start value, the lamp is turned on at the start value and them the light is dimmed down to the set level. Example: start=60 |

| force | integer 0-100 | 11-14 | 10 | Time duration of the starting value (measured in milliseconds). Example: force=20 |

| runtime | integer 0-60000 | 11-14 | 1000 | Runtime is the speed of changing the brightness from ‘min’ to ‘max’ (measured in milliseconds). Example: runtime=1000 |

| offset | integer (+/- 0…39) | 39-46 | '0' | sensor values offset; For example, offset is -3.8 :

Example: hw="offset='-3.8'" |

| io | char[28] | 98 | io='KKKKKKKKKKKKKKKKKKKKKKKKKKKK' | Each char is responsible for the type of a particular channel

Example: io='KKKKKKKKKKKKKKKKKKKKKKKKKKKK' |

| hw | string | 98 | - | hw="...", where

Example: 1hw="io='4---zdd----t--' pwm_invert=1 lbn_bright=255 f=1000"

|

| Only for Metaforsa 3.plus | ||||

| cfg | string | 98 | 9600/8N1 | cfg='SPEED/BPS', where

Example: 1hw="cfg='9600/8N1'"

|

| [Protocol] | string | 98 | — | Protocol setting is described by protocol parameter. The following

protocols are supported:

Example: 1hw="cfg='9600/8N1' modbus"

|

| echo | on; off | 98 | 'off' | For settings check out and testing echo parameter can be used. Module

echo-reply can be turned on or off with the help of this parameter.Echo parameter value:

Example: 1hw="cfg='9600/8N1' echo='off'"

|

1 <item addr="349:1" auto-period="600" cfgid="197" name="Lamp 1" type="lamp"/>

2 <item addr="349:2" auto-period="600" cfgid="197" name="Lamp 2" type="lamp"/>

3 <item addr="349:3" auto-period="600" cfgid="197" name="Lamp 3" type="lamp"/>

4 <item addr="349:4" auto-period="600" cfgid="197" name="Lamp 4" type="lamp"/>

5 <item addr="349:5" auto-period="600" cfgid="197" name="Lamp 5" type="lamp"/>

6 <item addr="349:6" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

7 <automation name="Eco" temperature-level="16"/>

8 <automation name="Comfort" temperature-level="22"/>

9 <automation name="Hot" temperature-level="25"/>

10 </item>

11 <item addr="349:7" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

12 <automation name="Eco" temperature-level="16"/>

13 <automation name="Comfort" temperature-level="22"/>

14 <automation name="Hot" temperature-level="25"/>

15 </item>

16 <item addr="349:8" cfgid="197" name="Radiator" temperature-lag="0.2" type="valve-heating">

17 <automation name="Eco" temperature-level="16"/>

18 <automation name="Comfort" temperature-level="22"/>

19 <automation name="Hot" temperature-level="25"/>

20 </item>

21 <item addr="349:9" cfgid="197" name="Jalousie" sub-type="120" type="jalousie"/>

22 <item addr="349:11" auto-period="600" cfgid="197" name="Dimmer 1" type="dimmer-lamp"/>

23 <item addr="349:12" auto-period="600" cfgid="197" name="Dimmer 2" type="dimmer-lamp"/>

24 <item addr="349:13" auto-period="600" cfgid="197" name="Dimmer 3" type="dimmer-lamp"/>

25 <item addr="349:14" auto-period="600" cfgid="197" name="Dimmer 4" type="dimmer-lamp"/>

26 <item addr="349:16" cfgid="197" name="Door 1" type="door-sensor"/>

27 <item addr="349:17" cfgid="197" name="Door 2" type="door-sensor"/>

28 <item addr="349:18" cfgid="197" name="Door 3" type="door-sensor"/>

29 <item addr="349:19" cfgid="197" name="Door 4" type="door-sensor"/>

30 <item addr="349:20" cfgid="197" name="Door 5" type="door-sensor"/>

31 <item addr="349:21" cfgid="197" name="Door 6" type="door-sensor"/>

32 <item addr="349:22" cfgid="197" name="Door 7" type="door-sensor"/>

33 <item addr="349:23" cfgid="197" name="Door 8" type="door-sensor"/>

34 <item addr="349:24" cfgid="197" name="Door 9" type="door-sensor"/>

35 <item addr="349:25" cfgid="197" name="Door 10" type="door-sensor"/>

36 <item addr="349:26" cfgid="197" name="Door 11" type="door-sensor"/>

37 <item addr="349:27" cfgid="197" name="Door 12" type="door-sensor"/>

38 <item addr="349:28" cfgid="197" name="Door 13" type="door-sensor"/>

39 <item addr="349:29" cfgid="197" name="Door 14" type="door-sensor"/>

40 <item addr="349:30" cfgid="197" name="Door 15" type="door-sensor"/>

41 <item addr="349:31" cfgid="197" name="Door 16" type="door-sensor"/>

42 <item addr="349:32" cfgid="197" name="Door 17" type="door-sensor"/>

43 <item addr="349:33" cfgid="197" name="Door 18" type="door-sensor"/>

44 <item addr="349:34" cfgid="197" name="Door 19" type="door-sensor"/>

45 <item addr="349:35" cfgid="197" name="Door 20" type="door-sensor"/>

46 <item addr="349:36" cfgid="197" name="Door 21" type="door-sensor"/>

47 <item addr="349:37" cfgid="197" name="Door 22" type="door-sensor"/>

48 <item addr="349:38" cfgid="197" name="Door 23" type="door-sensor"/>

49 <item addr="349:39" cfgid="197" name="Door 24" type="door-sensor"/>

50 <item addr="349:40" cfgid="197" name="Door 24" type="door-sensor"/>

51 <item addr="349:41" cfgid="197" name="Door 25" type="door-sensor"/>

52 <item addr="349:43" cfgid="197" name="IR receiver" type="ir-receiver"/>

53 <item addr="349:44" cfgid="197" name="RS485" type="com-port"/>

54 <item addr="349:90" cfgid="197" name="Current" system="yes" type="current-sensor"/>

55 <item addr="349:95" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

56 <item addr="349:96" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

57 <item addr="349:97" cfgid="197" name="Temperature" system="yes" type="temperature-sensor"/>

58 <item addr="349:98" cfgid="197" hw="out='LLLLLHHHB-' dm='LLLL' io='KKKKKKKKKKKKKKKKKKKKUKKKKKK-'" logic-ver="19" name="Temperature" sn="2533726919" system="yes" type="temperature-sensor"/>

59 <item addr="349:100" cfgid="197" name="RS232" type="com-port"/>