Metaforsa2 MF-14

| MF-14 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

| |||||||||||||

Einleitung

Das METAFORSA SMART HOUSE Installationshandbuch beschreibt das Verfahren für die Installation, die Montage, den Betrieb und die Einstellung des Systems. Bei der Arbeit mit dem System müssen Sie alle in diesem Handbuch aufgeführten Anforderungen strikt einhalten. Die Nichtbeachtung kann zu Schäden am Gerät, dessen Ausfall, Stromschlag, Feuer und anderen Folgen führen. Der Hersteller behält sich das Recht vor, ohne vorherige Ankündigung Änderungen an diesem Handbuch vorzunehmen. Dieses Handbuch ist ein wesentlicher Bestandteil des Systems und verbleibt beim Endkunden.

Merkmale

- 10 universelle Ausgänge werden unterstützt:

- Lichter

- NC/NO Heizungsventile

- Jalousien

- 1- oder 2-polige Schieber

- 1- oder 2-polige Ventile

- NC/NO Schlösser

- Gebläsekonvektoren

- 4 Dimmausgänge

- 24 diskrete Eingänge, die Folgendes unterstützen:

- Taster

- Schalter

- Reed-Schalter

- Lecksensoren

- Bewegungsdetektoren

- 4 digitale Eingänge für bis zu 8 Temperatursensoren

- Erweiterungsanschluss

- Relais mit AgSnO2-Kontakten für 80A 20ms Einschaltstrom

- Cloud-Anbindung und Steuerung aller Haussysteme

- Sprachsteuerung (Siri, Alexa, Google Home)

- Plugins-Engine ermöglicht die Erweiterung der Systemmöglichkeiten (z.B. Integration mit Satel, Philips Hue, IKEA-Lampen)

- Sicherheit gegen unbefugtes Eindringen durch RSA/AES256-Verschlüsselung

- Push-Benachrichtigungen vom System auf Ihr Telefon (auch über die Messenger Telegram und Viber möglich)

- Historie (Zählerdaten für 1 Jahr werden gespeichert)

- Plug and Play (Möglichkeit zur schnellen und benutzerfreundlichen Erweiterung des Systems)

- Regelmäßige System-Updates

- Große, ständig aktualisierte Datenbank mit Skripten, die alle Ihre Anforderungen erfüllen

- Automatische tägliche Backups über die Cloud mit der Möglichkeit, die ursprüngliche Konfiguration wiederherzustellen

- Offene API (die die Integration von Larnitech in andere Systeme ermöglicht)

- Interaktives und benutzerfreundliches LT SETUP-Webinterface für die erweiterte Konfiguration

- Plug and Play

- Es handelt sich um ein komplett einbaufertiges Smart Home System Kit

Sicherheitsanforderungen

Um das Risiko eines Brandes, eines elektrischen Schlages, einer Beschädigung des Systems und/oder von Personenschäden zu vermeiden, müssen die Installation und der Zusammenbau des Systems in Übereinstimmung mit den unten aufgeführten Anweisungen durchgeführt werden:

- Alle Anschlussarbeiten müssen im stromlosen Zustand durchgeführt werden;

- geeignete Werkzeuge und persönlichen Schutz gegen elektrischen Schlag verwenden;

- Verwenden Sie keine beschädigten Kabel, Drähte und Steckverbinder;

- Vermeiden Sie das Knicken von Kabeln und Drähten;

- Kabel und Drähte nicht durch übermäßige Kraftanwendung einklemmen oder knicken. Andernfalls können die Innenleiter der Kabel und Drähte abisoliert oder gebrochen werden;

- Verwenden Sie zum Anschließen keine Steckdose mit schlechten Kontakten;

- Überschreiten Sie nicht die in diesem Handbuch angegebenen Grenzwerte für die Lastparameter;

- Der Abschnitt der Versorgungsleiter unterliegt den Spezifikationen für die Stromdichtegrenze, den Isolierungstyp und das Drahtmaterial. Leichte Abschnitte können zu Kabelüberhitzung und Feuer führen.

Bei Arbeiten am System nach der Spannungsversorgung NIEMALS:

- Stecker anschließen/abziehen;

- Module und Sensoren öffnen.

Systemkonfiguration und Zweck

Zweck des Systems

METAFORSA SMART HOUSE ist eine fertige Lösung für die Automatisierung von Wohn- und Geschäftsräumen sowie Hotelkomplexen, die die am meisten gewünschten Funktionen von Smart House beinhaltet.

Das Gerät verfügt über 10 Steuerkanäle, 4 Dimmkanäle, 24 Eingangssensorkanäle und einen Anschluss für digitale Sensoren.

| Über Universalausgänge können gesteuert werden: | Universaleingänge ermöglichen den Anschluss von: |

|---|---|

| Beleuchtung | Tasten/Schalteinheiten |

| Buchsenverbinder | Magnetische Reed-Schalter |

| Fußbodenheizung | Bewegungssensoren |

| Vorhang-/Torantriebe | Leckagesensoren |

| Wasserversorgungs-/Heizungsventile |

Anschluss für digitale Sensoren

An den Anschluss für digitale Sensoren können Sie eine Vielzahl von digitalen Sensoren anschließen, z. B. Temperatursensoren, Umgebungslicht, Luftfeuchtigkeit und andere.

Erweiterungsanschluss

Die Erweiterungsschnittstelle ermöglicht es Ihnen, das System durch den Anschluss von Zusatzgeräten zu erweitern, wie z. B. das Steuermodul für LED-Beleuchtung, Dimmer, Messgeräte und andere Elemente.

Das komplett einbaufertige Paket enthält die grundlegende Hardware und Software.

Paketinhalt

Das Paket wird standardmäßig geliefert:

| Großrechner METAFORSA MF-14.А | 1 St. |

| Netzgerät MEANWELL DR-15-12 | 1 St. |

| Bewegungssensor CW-MSD | 3 St. |

| Leckagesensor FW-WL.A | 2 St. |

| Temperatursensorelement FW-TS.A | 4 St. |

| Magnetischer Reedschalter (Fenster-/Türpositionssensor) | 4 St. |

| Ethernet-Kabel-Rauschfilter | 1 St. |

| Netzkabel | 1 St. |

Grundlegende technische Daten des Systems

Die grundlegenden Spezifikationen und Eigenschaften des Moduls METAFORSA MF-14.A sind in Tabelle 1 aufgeführt

| Spezifikation | Bedeutung |

|---|---|

| Ausgabeports | |

| Anzahl der geschalteten Kanäle | 10 |

| Anzahl der geschalteten Gruppen | 10 |

| Anzahl Dimmkanäle | 4 |

| Kommutierungsspannung | 0-250 V AC/DC |

| Spitzenlast (ein Kanal) | 16A |

| Spitzenlast (Gerät) | 160A |

| Maximale Last pro Dimmkanal | 0,5A (110W bei 220V) |

| Dimmertyp | MOSFET |

| Dimmerlasttyp | R,C |

| Dimmart | Hinterkante |

| Anschlussart des Stromversorgungskabels | Verbinder |

| Zulässiger Querschnitt des Stromversorgungskabels zum Anschluss an die Steckdose: Einleiterkabel Mehrleiterkabel Mehrleiterkabel mit Spitze |

0,5 … 4mm2 0,5 … 4mm2 0,5 … 2,5 mm2 |

| Eingabeports | |

| Anzahl der diskreten Eingänge | 24 |

| Anzahl der digitalen Eingänge | 4 |

| Aktuelle Maximalbelastbarkeit der Gleichspannungsanschlüsse | 50mA |

| Andere | |

| Betriebsumgebungstemperatur | 0 … +45°С |

| Lager-/Transporttemperatur | -20 … +60°С |

| Zulässige Luftfeuchtigkeit | 0 … 95 % (nicht kondensierend) |

| Stromversorgung | 12 … 27,5 V DC 24 V, 0,75 A Empfohlen |

| Maximale Nachfrage | 0,5À |

| Verfügbare Schnittstellen | Ethernet, CAN, OneWire |

| Bustyp | CAN (4-Draht) |

| CAN (4-Draht) | 800 m* (Twisted Pair 5 Katze) |

| CAN-Kabeltyp | FTP Cat 5E |

| CAN-Verbindungstyp | Verbinder |

| Maximale Länge der digitalen Leitung | 30 m |

| Digitaler Leitungstyp | UTP/FTP Cat 5E |

| Maximale LAN-Länge | 100 m |

| LAN-Kabeltyp | UTP/FTP Cat 5E |

| LAN-Verbindungstyp | Anschluss RJ-45 |

| Maßangaben | 9 HE, 156 x 110 x 58 mm |

| Schalenmaterial | ABS-Kunststoff |

| Gehäuse | IP40 |

| Geräteinstallationstyp | DIN-Schiene (EN 60715) |

| Gewicht | 400 g |

* – bei langen Leitungen ist die Installation zusätzlicher Netzteile erforderlich; Die maximale Länge der Leitung kann durch verschiedene Störfaktoren reduziert werden

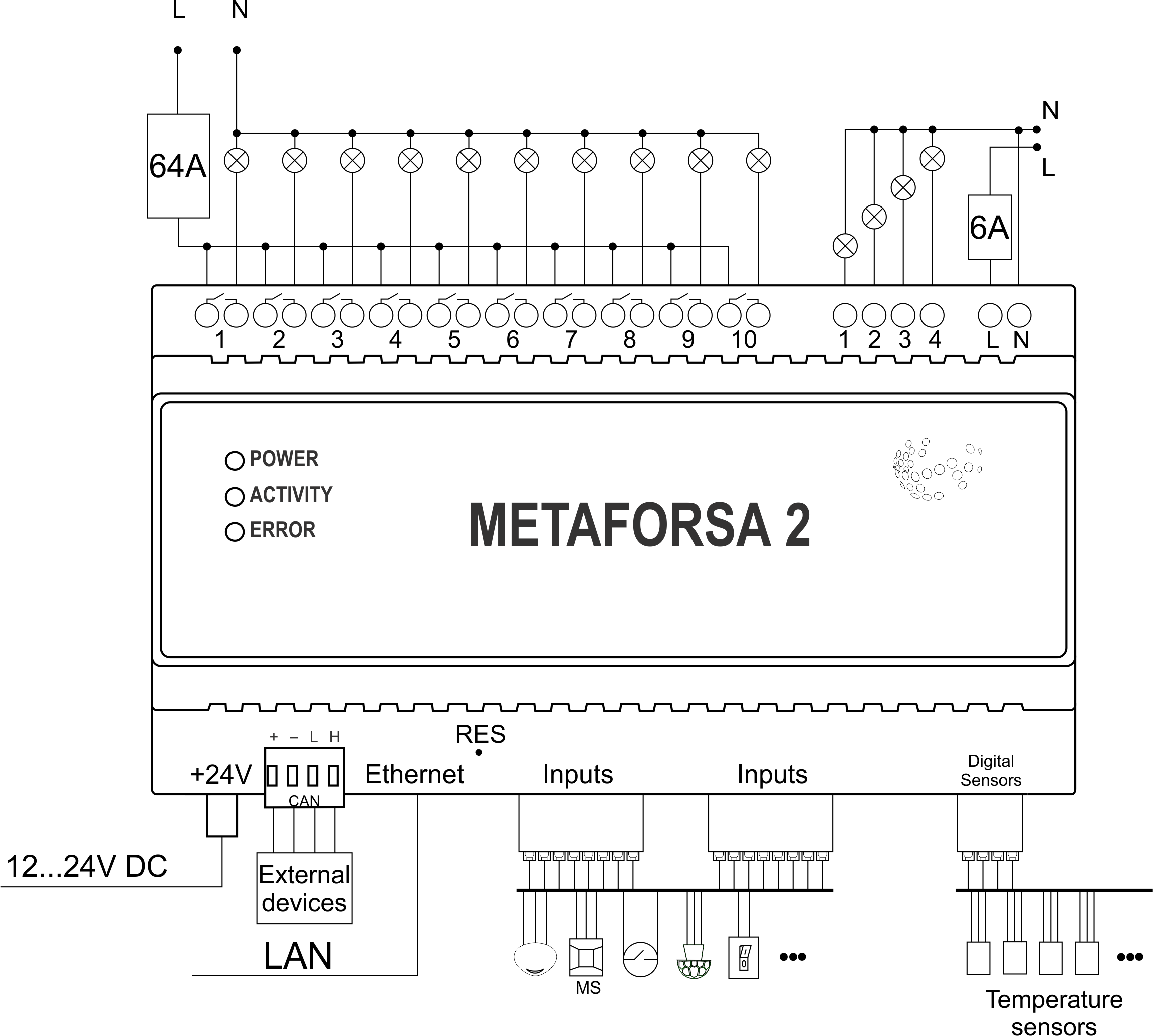

Allgemeine Struktur des Systems

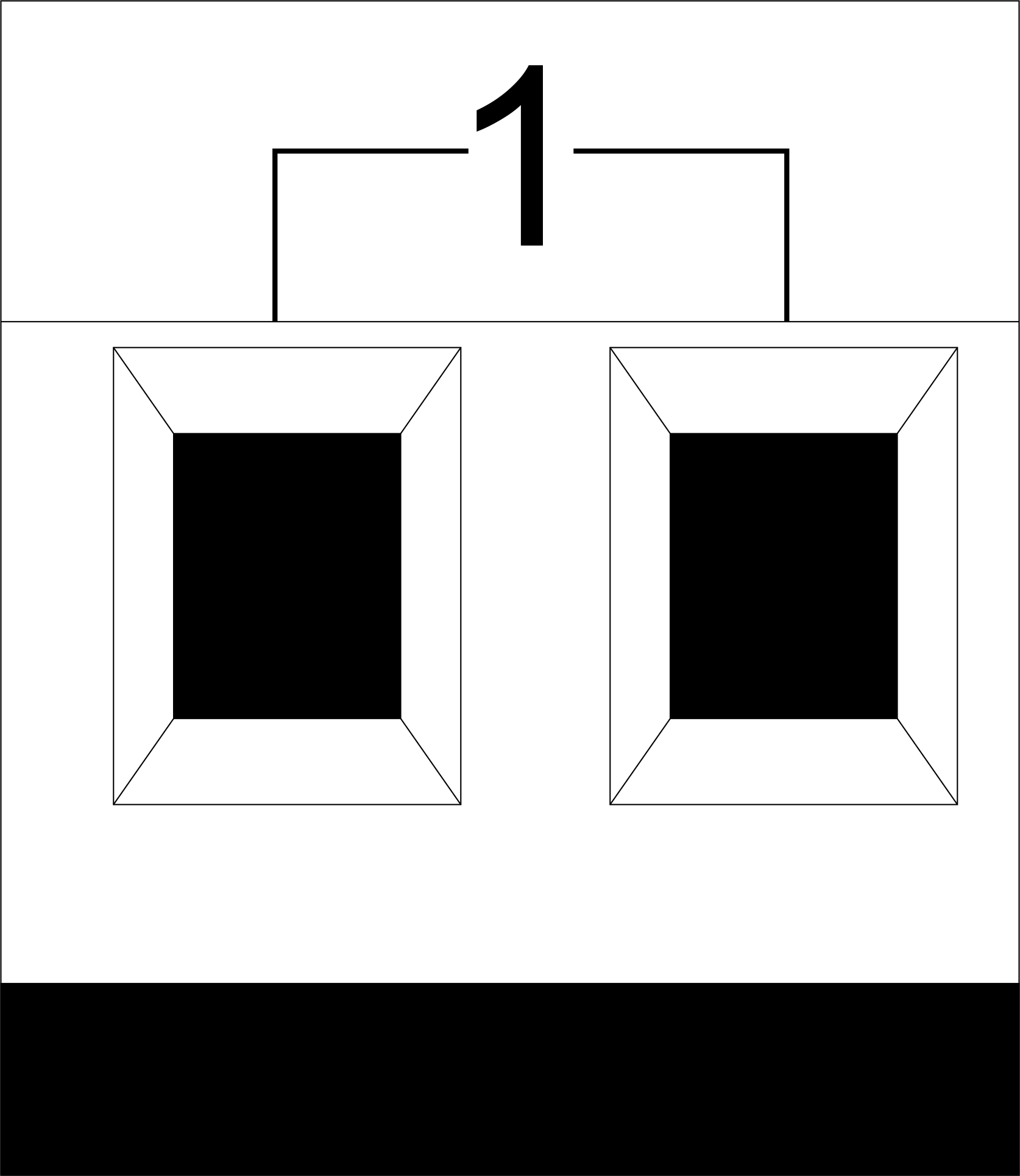

Die Gesamtansicht des Moduls ist in Abb. 1 dargestellt.

| 1 | — Anschluss für Lastaufbringung |

| 2 | — Steckverbinder für Dimmlampenanwendungen |

| 3 | - Stecker |

| 4 | — Ethernet-Netzwerkanschluss |

| 5-6 | — Anschlüsse für digitale Sensoren und Taster/Schalteinheiten |

| 7 | — OneWire-Schnittstellenstecker (für digitale Sensoren) |

| 8 | — Anschluss für Erweiterungsmodul. |

'Übersicht über die externen METAFORSA-Geräteanschlüsse:

Oben auf dem Gehäuse (Abb. 1) befindet sich:

- Anschluss (1) – Geräteverbindung;

- Anschluss (2) – Anschluss zum Dimmen von Lampen;

Auf der Unterseite des Gehäuses (Abb. 1) befindet sich:

- Anschluss (3) – Anschluss für die Stromversorgung des Moduls;

- Anschluss (4) – Ethernet-Netzwerkverbindung;

- Anschlüsse (5-6) – vier Sechspunkt-Anschlüsse für den Anschluss digitaler Sensoren – Bewegungs-, Leckage-, Reed-Schalter-Sensoren und *Tasten-/Schalteinheitssensoren;

- Anschluss (7) – OneWire-Busverbindung für digitale Sensoren;

- Anschluss (8) – Erweiterungsmodulanschluss.

Die physische Konfiguration und die Kontaktpunktzuordnung jedes Steckverbinders sind in Tabelle 2 dargestellt

| Connector | Contact | Assignment |

|---|---|---|

|

1-10 | Load application (light lamps, thermal actuators, etc.) |

| D1-4, L, N | Load application (dimming lamps) | |

| Device status indicators | The module status indicators are described in table 3 | |

|

+24V GND |

+24V — module power supply by an external 24 V power supply GND — common |

|

RJ45 | Connector for LAN connectivity |

| In1-12, In13-24 GND | Controlling devices connection (buttons, magnetic reed switches, motion or leakage sensors): +12V — sensor power output +12 V In1 … In24 — logic inputs (0-12 V) GND — common | |

|

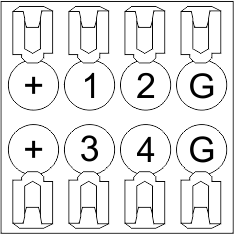

OneWire | Digital sensors connection (temperature) VCC — sensors power supply output +5V OW1-OW4 — OneWire data buses GND — common |

|

VCC GND L H |

External modules connection for CAN-bus VСС — 24V output for external devices power supply GND — common L — CAN-L data bus H — CAN-H data bus |

| Indicator | Status | Description |

|---|---|---|

| Power | Power | |

| Power not available | ||

| Activity | Data communication | |

| Data communication not available | ||

| Error | No errors | |

| Communication error | ||

| Module overheat | ||

| Dimmer outputs module overload | ||

| Absence of power on dimmers, if in configuration |

System installation and assembly

Before connecting the system, you must:

- site the sensor and actuators (if not pre-installed), set the sensors and actuators;

- site the module and power supply.

Note: The module must be installed near the power supply voltage source.

- The power of circuit breaker assembly must comply with the load capacity;

- Nothing else than the phase conductors can be connected to the module, the neutral wire is connected separately.

Typical diagram of METAFORSA MF-14.A module connection is shown in fig. 3.

Connection of the actuators

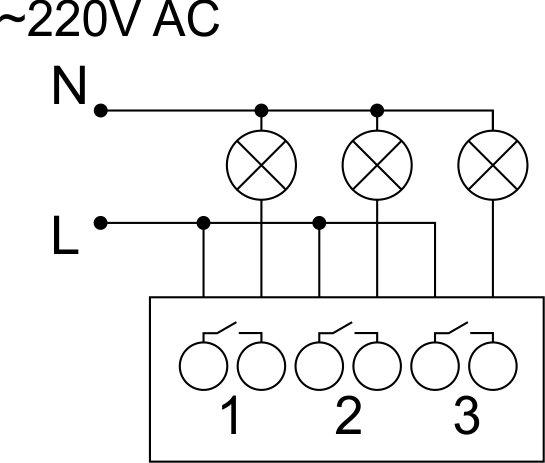

Connection of the lights/electric contactor/heating thermal actuator

Fig. 4 |

Such actuators as light, electric contactor, heating thermal actuator should be switched on any of the outputs 1 – 10, the neutral wire and the ground wire should be connected directly to the switchboard. The example of connection is shown in Fig.4. |

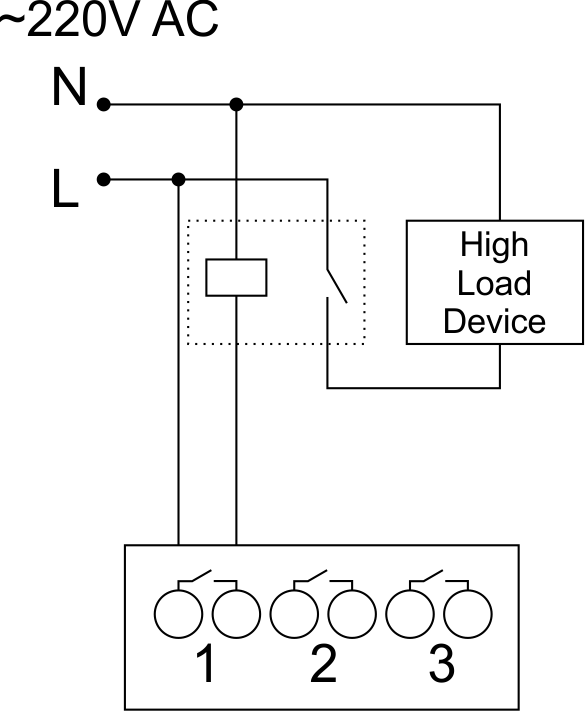

Connection of high load device

|

Recomended contactors:

|

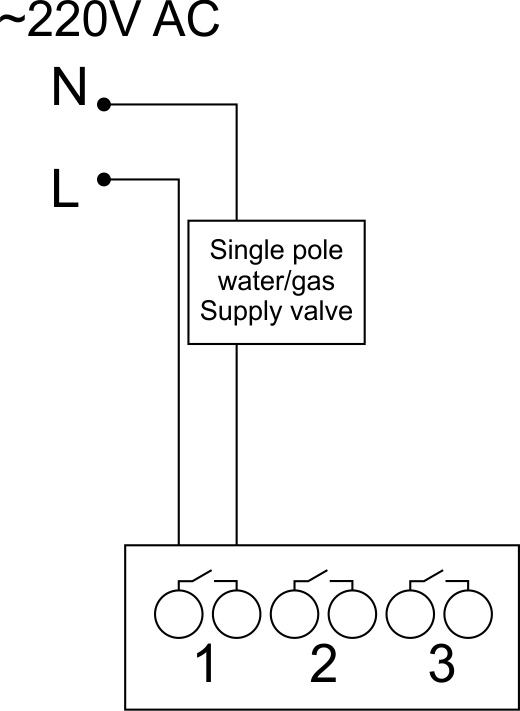

Connection of single-pole water/gas supply valve

| Caution: Before applying power to the load, make sure that the output configuration of METAFORSA module is correct. The incorrect configuration or incorrect connection can cause the module failure and/or failure of the equipment connected to it, and even a fire. | |

Fig. 5 |

The single pole water/gas supply valve is connected to any of the outputs of 1 – 10, the (neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.5. |

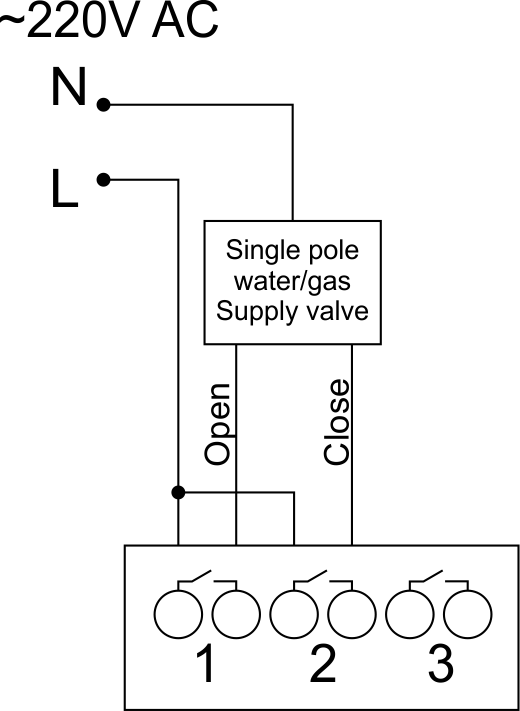

Connection of double-pole water/gas supply valve

| Caution: Before applying power to the valve, it is necessary to ensure the output configuration of METAFORSA module is correct. The incorrect configuration can cause the voltage application simultaneously to both channels of the valve, which may result in the module failure and/or failure of the equipment connected to it, and even a fire. | |

Fig. 6 |

Two adjacent contact points (for example, 3, 4) are used to connect the double-pole water/gas supply valve; in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.6. |

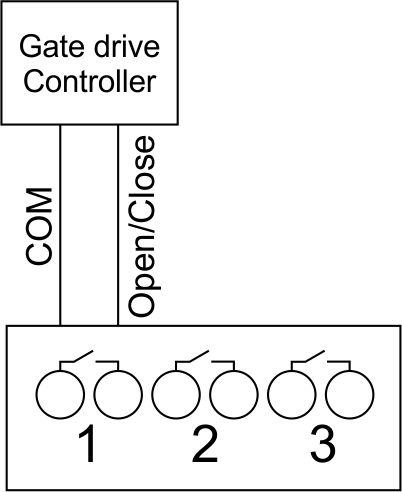

Connection of single-pole gate actuator

| Caution: Before applying power to the module, you should properly configure access to the application. The contacts incorrectly configured can result in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 7 |

Any contact point (for example, 3) is used to connect the single-pole gate drive controllers. The example of connection is shown in Fig.7. |

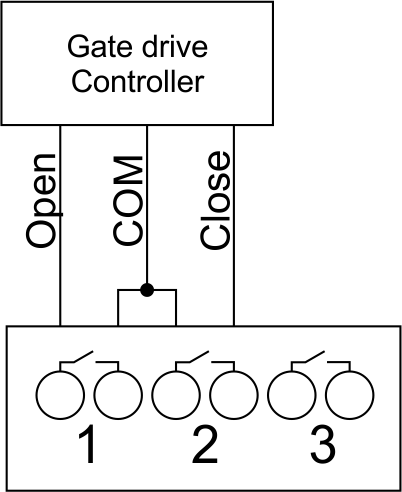

Connection of double-pole gate actuator

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 8 |

Two adjacent contact points (for example, 3, 4) should be used to connect the double-pole gate drive controller. The example of connection is shown in Fig.8. |

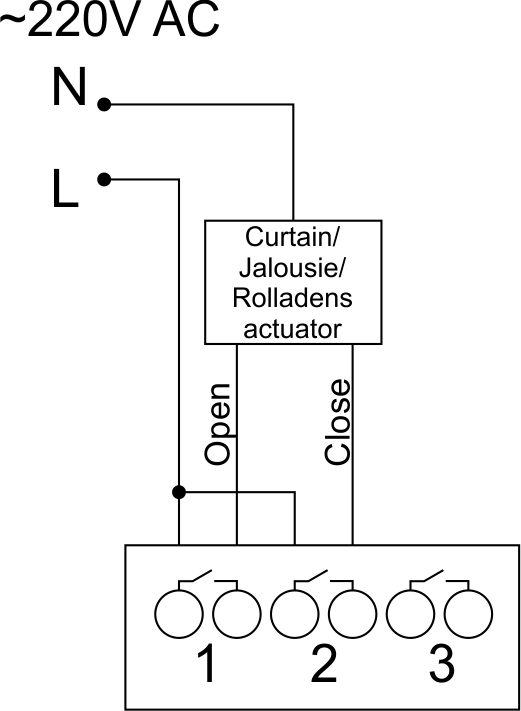

Connection of curtain/jalousie/shutter actuator with 220V force control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 9 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator, in these conditions the neutral wire and the ground wire are connected directly to the switchboard. The example of connection is shown in Fig.9. |

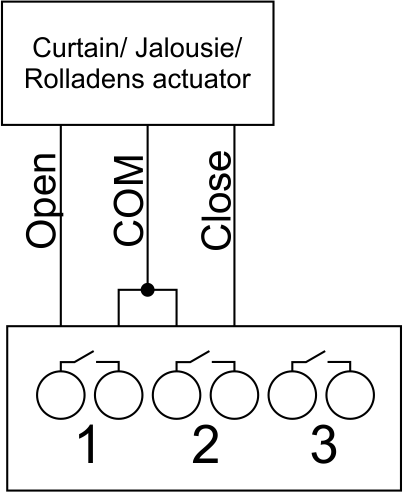

Connection of curtain/jalousie/shutter actuator with low-voltage control

| Caution: Before applying power to the module, you must properly configure the outputs in the application. The contacts configured incorrectly can lead to simultaneous power supply to both channels, resulting in the module failure and/or failure of the equipment connected to it, and even a fire.

| |

Fig. 10 |

Two adjacent contact points (for example, 3, 4) should be used to connect the curtain/jalousie/rolladens actuator with low-voltage control. The example of connection is shown in Fig.10. |

Connection of sensing elements/switches/buttons

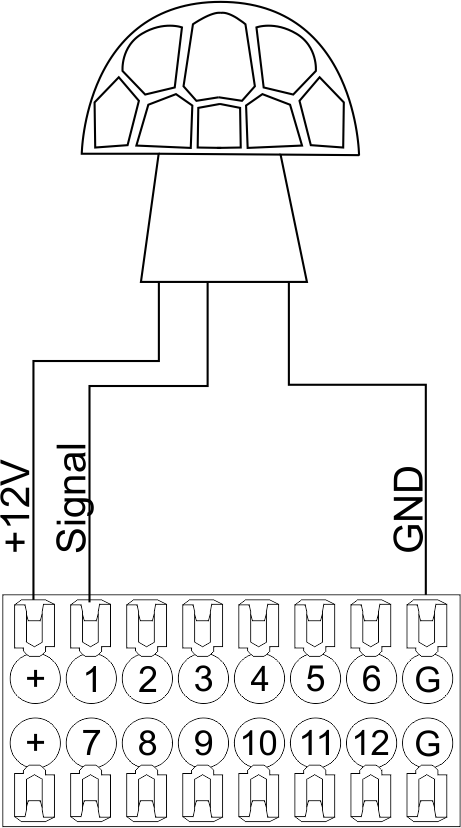

Connection of motion sensors

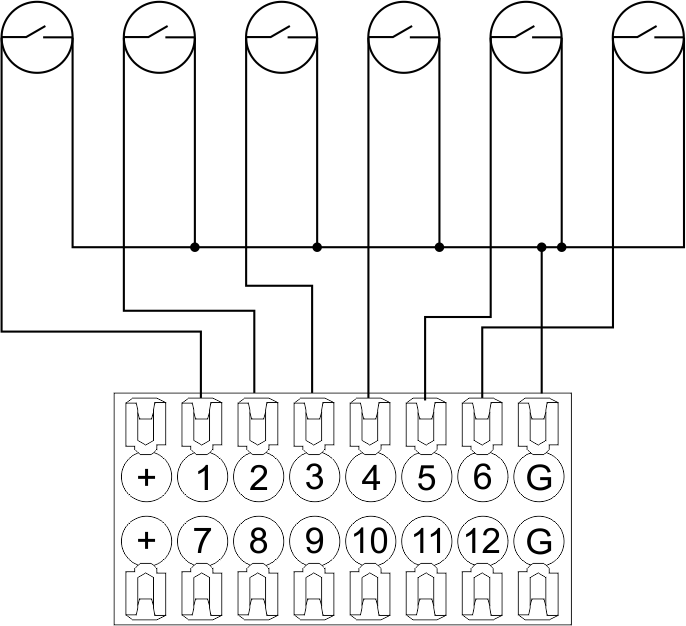

The motion sensors should be connected to any free input in1-in24; in these conditions their power is connected to the contact points of +12V and GND of the relevant group. The example of connection is shown in Fig.11.

Fig. 11

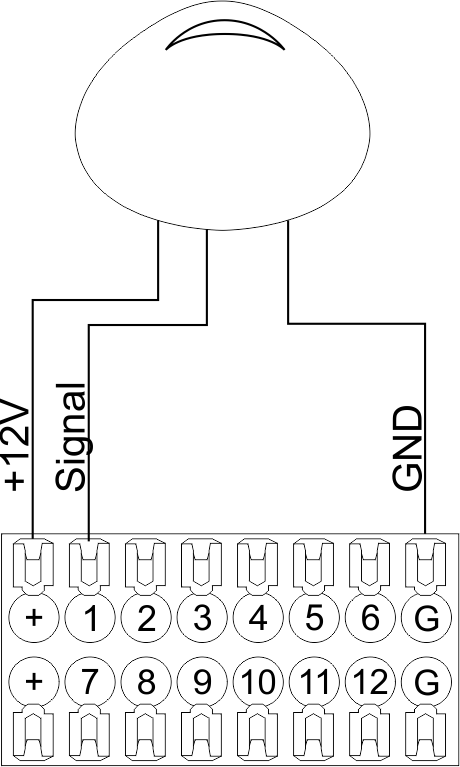

Connection of FW-WL.A leakage sensors

FW-WL.A leakage sensors are connected to any free input in1 – in24, in these conditions the power should be connected to +12V and GND points of the relevant group. The example of connection is shown in fig. 12.

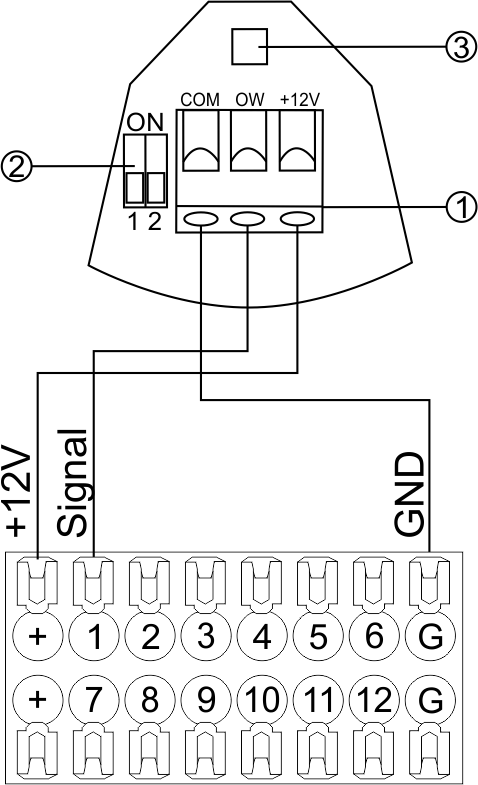

Fig12 |

Fig13 |

Configuration and connection of the FW-WL.A sensor 1. Terminals:

- +12V — sensor power is connected to the contact point of METAFORSA “+12V”;

- OW — sensor pickup signal;

- GND — common, connected to GND contact of METAFORSA.

2. Sensor preset switch (optionally):

- 1 — sensor sensitivity (ON – high, OFF – low);

- 2 — indicator colour setting (ON – blue, OFF – green).

3. LED status indicator.

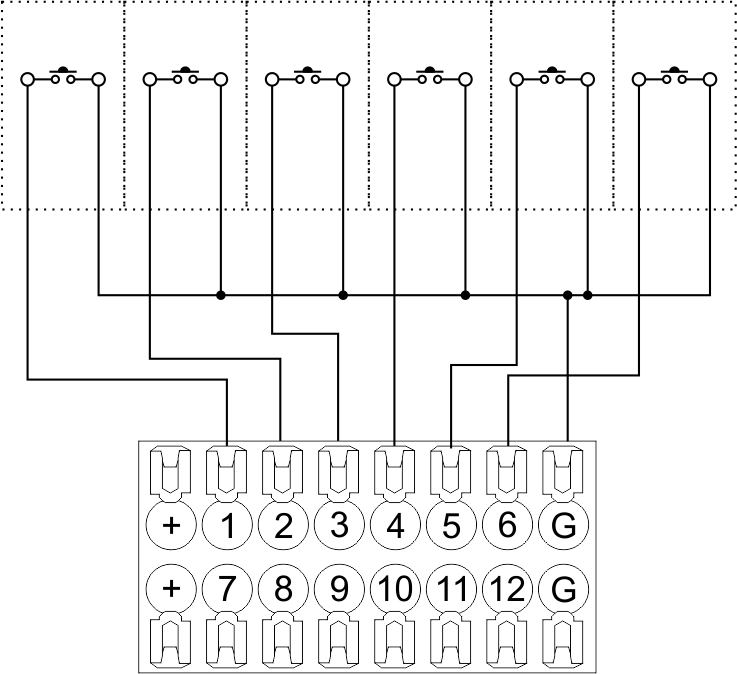

Connection of buttons/switches/magnetic reed switches

Buttons and reed switches are connected to any free input in1-in24, while their second contact point is connected to GND point of the relevant METAFORSA module group, + 12V power outputs – not in use. The example of connection is shown in Fig. 14-15.

Fig14 connection of buttons/switching units |

Fig15 connection of the magnetic reed switches (window/door position sensors) |

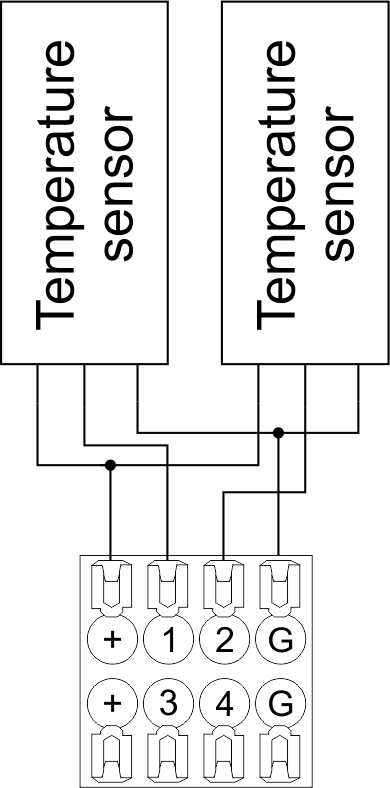

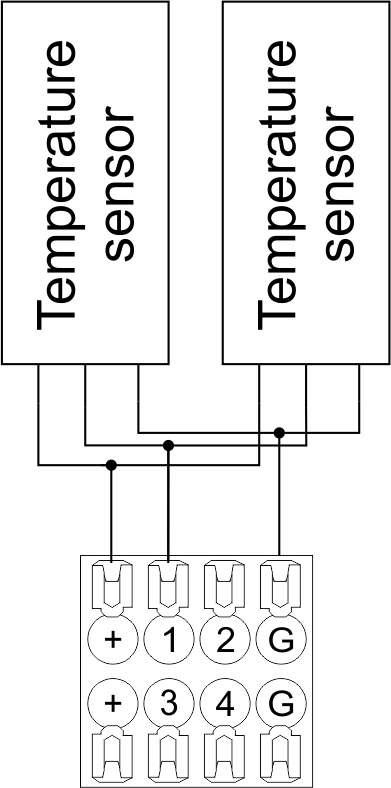

Connection of digital sensors

The OW adapter (Fig. 16a) is supplied along with METAFORSA module with the possibility to connect up to 8 digital sensors to it. In these conditions, several devices can be connected to one channel (Fig. 16b). The connected sensors are detected automatically and do not require any original setting.

Fig16 a |

Fig16 b |

Configuration and connection of the OW adapter

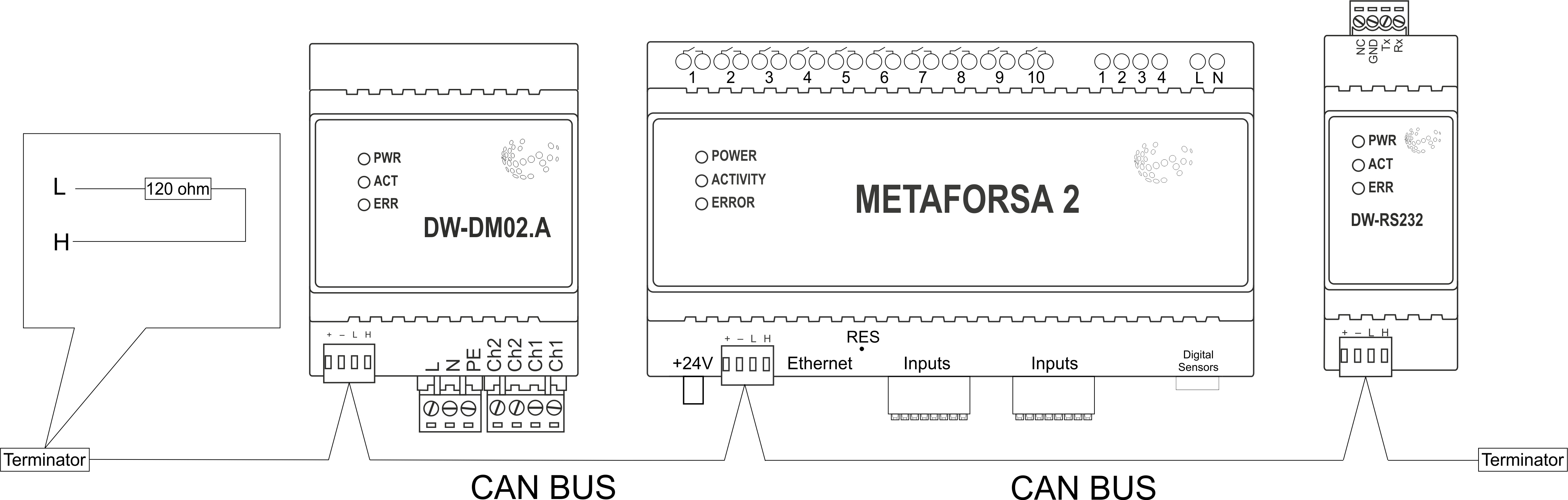

Connection of auxiliary equipment.

Expansion modules include Larnitech equipment connected through the CAN-bus. Such equipment includes: dimmers, RGB-backlit control modules, multimode sensors, etc. The equipment connected to the expansion port is defined automatically and does not require any preset tuning. Connector contact pin assignment is defined in Table 4. The example of connection is shown in Fig. 17.

|

| Caution! The 120 ohm terminating resistors should be installed at the end connectors between L and H contact points of CAN-bus. Ensure the connection is correct. The incorrect connection may cause sensor and/or module malfunction. |

Module installation and connection procedure

- Install the module in the switchboard on the DIN-rail and fix it with the special latch on the module base.

- Fasten the supply unit on the left side of the module.

- Connect the connector (4) having the noise filter pre-installed which is supplied complete with the module.

- Connect the connectors (5), (6).

- Connect the connectors (1), (2).

- Connect the connector (3).

- Apply power to the supply unit of METAFORSA module.

- Wait until the module is loaded, then configure it in accordance with the System Setup Instructions.

- Apply power to the connectors (1), (2).

- Check all equipment for proper operation.

METAFORSA module shut-off and deinstallation procedure

- De-energize the module by disconnecting the circuit breaker assembly of the load power supply and METAFORSA module supply unit. Verify the voltage is absent on the terminals (1), (2) of the connector wires and on the input terminals of the supply unit.

- Disconnect the load power supply connectors (1), (2).

- Disconnect the connector (3).

- Disconnect the connectors (4)-(6).

- Remove the module from the DIN-rail, releasing the latch at the bottom of the module base.

Hardware setup

To configure and control METAFORSA SMART HOUSE, you must install Larnitech software on your smartphone or tablet, which is available in App Store and Play Market. After installation, follow the System Setup Instructions.

Fault diagnostics and handling

The following are some possible faults and ways of fault handling. If you have any difficulty, or face the fault undeclared here, please contact the Technical Support: [1] or [support@larnitech.com]. There are also some tips in the FAQ section at our website [2].

The actuators do not operate:

- ensure the outputs are properly configured in the application (see System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.6;

- ensure the power is supplied to the input power contact , i.e. all circuit breaker assembly are ON.

- verify the operability of the connected equipment.

The module is off, indication absent:

- check the connection to 24V supply unit as shown in table 2 (contacts pin assignment);

- check the connection of the supply unit to 220V power mains, the indicator should be ON.

Network connection fault:

- ensure the Ethernet cable is properly wired and connected to the connector;

- ensure the LED status indicators are ON on the Ethernet connector;

- check the LAN configuration is correct, Ethernet cable loops are absent;

- METAFORSA module and the device you are connecting from are in the same network.

hold integer 0-10000 1-10 by default hold is the same as runtime hold is the bridging time in miliseconds, is used for gate and jalousie, lock; Example: hold=3500

The sensors do not operate:

- ensure the inputs are properly configured in the application (System Setup Instructions);

- check the connection is correct in accordance with table 2 and paragraph 3.7;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the power supply availability on the sensors;

- check the integrity of lines laid to the sensors.

The auxiliary equipment does not operate:

- check the connection is correct in accordance with table 2 and paragraph 3.8-9;

- ensure the METAFORSA module is ON: circuit breaker assembly is closed, indication on the supply unit is ON, the module indication corresponds to the operating status – table 3;

- check the integrity of the CAN lines, voltage supply on the modules.

HW Settings

| Name | Type, range | SUBID | Default | Description |

|---|---|---|---|---|

| runtime | integer 0-100 | 1-10 | 15 | runtime is the open/close time in seconds, is used for jalousie, gate, valve(2 pole);

|

| runtimeopen | integer 0-60000 | Blinds subId | Runtimeopen is the open time in milliseconds, is used for blinds; Example: runtimeopen=15000 | |

| runtimeclose | integer 0-60000 | Blinds subId | Runtimeclose is the close time in milliseconds, is used for blinds; Example: runtimeclose=15000 | |

| hold | integer 0-10000 | 1-10 | 500 | hold is the bridging time in milliseconds, is used for gate and jalousie (by default hold is the same as runtime for jalousie and gate), lock; Example: hold=3500 |

| def | string 'ON' | 1-10 | 'OFF' | def is the element status is set after restart, is used for lamp, heating, valve(1 pole); Example: def='ON' |

| stop | Char ‘R’ | 1-7 | – | (for 2-pole gate and blinds) If it is declared then by Stop command during the motion, the same impulse appears as it was at the beginning of the motion. Pole, an which the stop-impules is formed, is defined by the parameter Stop value. If it is ‘r’ or ‘R’ then stop-impulse is produced on the opposite to the start-impulse pole. If any other value is delcared (e.g., ‘d’ ) then the stop-impulse is on the same pole. If a Runtime passed after the beginning of the motion then the stop-impulse is not formed. Example: stop=’r’ |

| out | char[10] | 98 | 'LLLLHHHHP-' | Each char is responsible for the type of a particular channel

Example: out='LLB-G-V-W-' |

| dm | char[4] | 98 | ‘LLLL’ | Each char is responsible for the type of a particular channel

Example: dm=’skl-‘ |

| def | integer 0-250 | 11-14 | 100 | The default brightness level in case of a power reset (1..250). Example: def=250 |

| min | integer 0-100 | 11-14 | 0 | Minimum dimming level, example: min=10 |

| max | integer 0-100 | 11-14 | 100 | Maximum dimming level, example max=95 |

| start | integer 0-100 | 11-14 | 0 | The Start function is used for lamps that lack the minimal voltage to get turned on. If the set value is lower than the start value, the lamp is turned on at the start value and them the light is dimmed down to the set level. Example: start=60 |

| force | integer 0-100 | 11-14 | 10 | Time duration of the starting value (measured in milliseconds). Example: force=20 |

| runtime | integer 0-60000 | 11-14 | 1000 | Runtime is the speed of changing the brightness from ‘min’ to ‘max’ (measured in milliseconds). Example: runtime=1000 |

| offset | integer (+/- 0…39) | 39-46 | '0' | sensor values offset; For example, offset is -3.8 :

Example: hw="offset='-3.8'" |

| in | char[24] | 98 | 'BBBBBBBBBBBBMMMLLLKKKKKK' | Each char is responsible for the type of a particular channel

Example: in='MMMMMMMMMMMMLLLLLLLLLLLL' 12 motion sensors and 12 leak-sensors; in='BBBBBBBBSSSSSSBBBBSSSSSS' 12 buttons; 12 switches. |

1<item addr="339:1" auto-period="600" cfgid="40" hw="def='ON'" name="Lamp" type="lamp" uniq_id="3779">

2<item addr="339:2" cfgid="40" hw="def='ON'" name="Radiator" type="valve-heating" uniq_id="3780">

3 <automation name="Eco" temperature-level="16" uniq_id="3781"/>

4 <automation name="Comfort" temperature-level="22" uniq_id="3782"/>

5 <automation name="Hot" temperature-level="25" uniq_id="3783"/>

6</item>

7<item addr="339:3" cfgid="40" hw="runtime=9" name="Jalousie" sub-type="120" type="jalousie" uniq_id="32"/>

8<item addr="339:5" cfgid="40" hw="runtime=13" name="Gate" sub-type="120" type="gate" uniq_id="3784"/>

9<item addr="339:7" cfgid="40" hw="hold=4600" name="Gate" sub-type="120" type="gate" uniq_id="3785"/>

10<item addr="339:8" cfgid="40" hw="runtime=10" name="Valve" type="valve" uniq_id="3786"/>

11<item addr="339:11" cfgid="40" name="Motion" type="motion-sensor" uniq_id="17"/>

12<item addr="339:12" cfgid="40" name="Motion" type="motion-sensor" uniq_id="18"/>

13<item addr="339:13" cfgid="40" name="Motion" type="motion-sensor" uniq_id="19"/>

14<item addr="339:16" cfgid="40" name="Leak" type="leak-sensor" uniq_id="21"/>

15<item addr="339:17" cfgid="40" name="Leak" type="leak-sensor" uniq_id="41"/>

16<item addr="339:19" cfgid="40" name="Switch" type="switch" uniq_id="22"/>

17<item addr="339:20" cfgid="40" name="Switch" type="switch" uniq_id="23"/>

18<item addr="339:21" cfgid="40" name="Switch" type="switch" uniq_id="24"/>

19<item addr="339:22" cfgid="40" name="Switch" type="switch" uniq_id="25"/>

20<item addr="339:23" cfgid="40" name="Door" type="door-sensor" uniq_id="26"/>

21<item addr="339:24" cfgid="40" name="Door" type="door-sensor" uniq_id="27"/>

22<item addr="339:25" cfgid="40" name="Door" type="door-sensor" uniq_id="28"/>

23<item addr="339:26" cfgid="40" name="Door" type="door-sensor" uniq_id="29"/>

24<item addr="339:30" cfgid="40" name="Temperature" type="temperature-sensor" uniq_id="3772"/>

25<item addr="339:31" cfgid="40" name="Temperature" type="temperature-sensor" uniq_id="3773"/>

26<item addr="339:32" cfgid="40" name="Temperature" type="temperature-sensor" uniq_id="3774"/>

27<item addr="339:33" cfgid="40" hw="offset='-10.8'" name="Temperature" type="temperature-sensor" uniq_id="3775"/>

28<item addr="339:34" cfgid="40" hw="offset='25.1'" name="Temperature" type="temperature-sensor" uniq_id="3776"/>

29<item addr="339:35" cfgid="40" name="Temperature" type="temperature-sensor" uniq_id="3777"/>

30<item addr="339:36" cfgid="40" name="Temperature" type="temperature-sensor" uniq_id="3778"/>

31<item addr="339:98" cfgid="40" hw="out='LHB-G-XV--' in='MMM--LL-BBBBKKKK'" name="Temperature" system="yes" type="temperature-sensor" uniq_id="30"/>